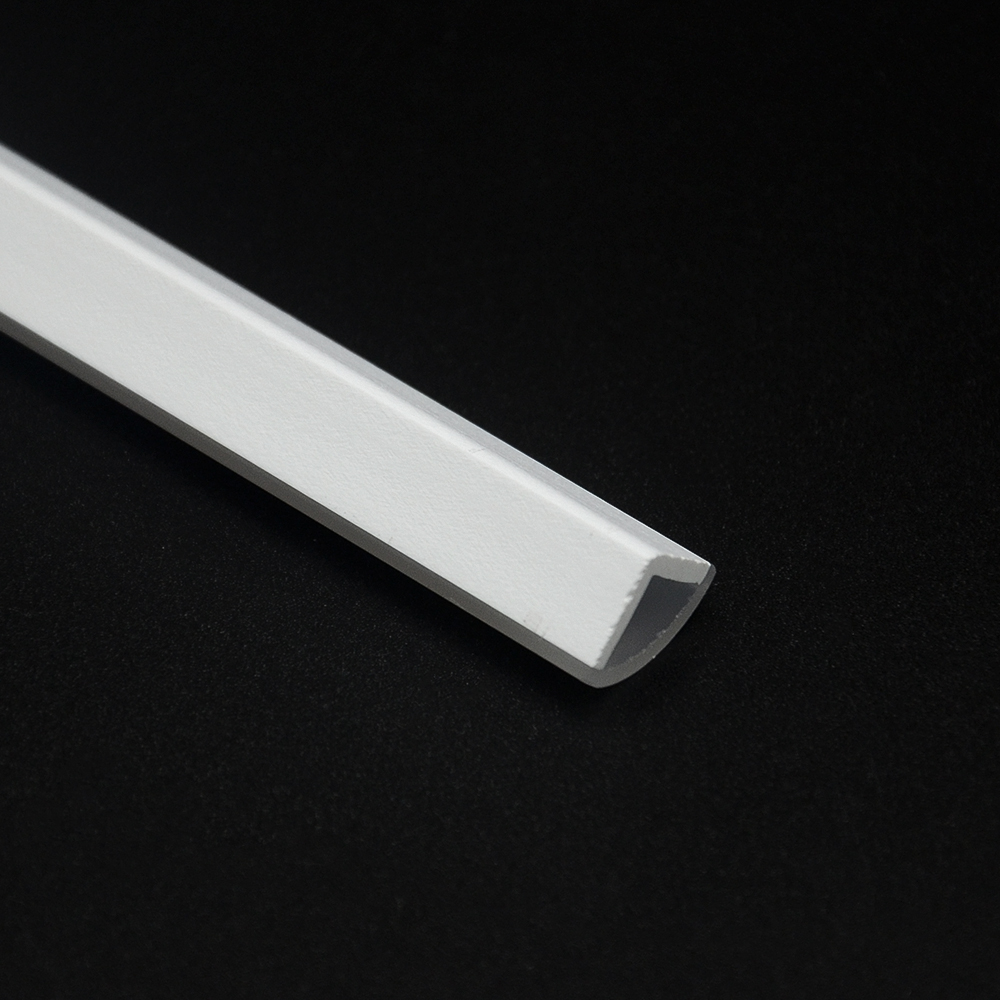

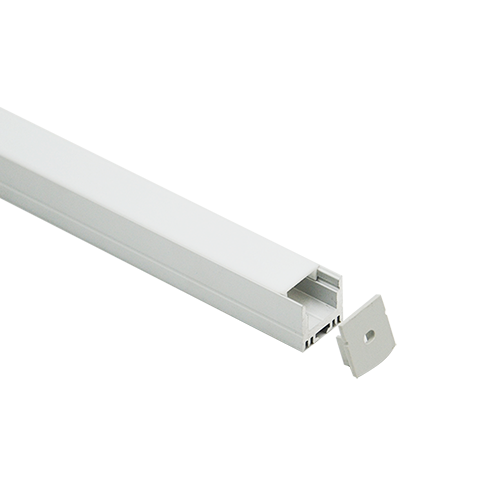

Technical Specifications

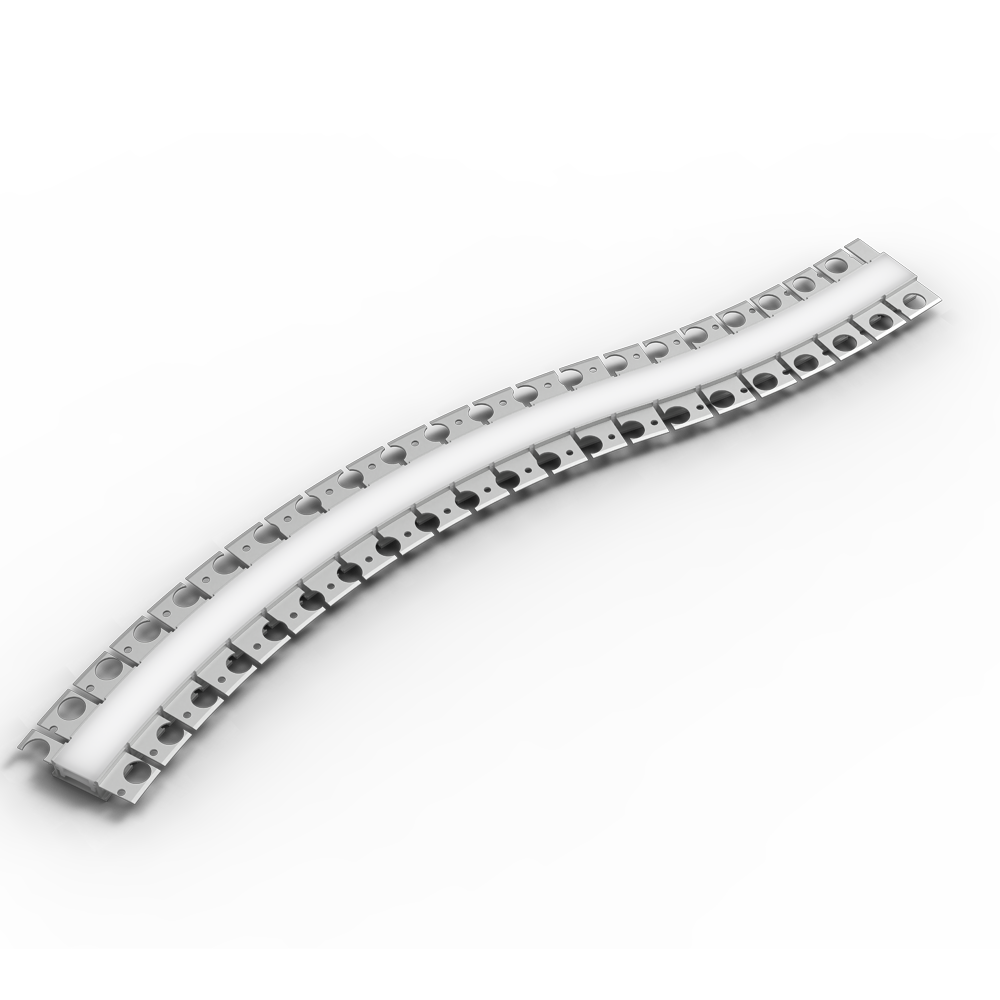

| Model: | HL-BAPL067-F |

| Material Surface: | PMMA |

| Lighting source width | 8mm |

| Profile Size: | W:10.3mm * H: 10.3mm |

| Installation Method: | Surface Mount |

| OEM/ODM/Distributor Wholesale/Customized purchasing: | Support |

Downloads

Customer Cases

In San Francisco’s booming bridge infrastructure lighting market—where durability and aesthetics are key—the “8 mm profile light” HL-BAPL067-F excels. Its IP67 waterproof design withstands the city’s foggy, coastal conditions, making it perfect for illuminating bridge railings and structural edges. The 8mm slim profile blends unobtrusively with bridge architecture, while the imported PMMA diffuser casts uniform, soft light that highlights safety features without glare. Screw-free end caps and stainless steel clips speed up installation for contractors, and its double-color surface resists corrosion. CE-certified, it’s a trusted choice for San Francisco’s bridge waterproof lighting projects.

Why Choose HLLED 8 mm profile light ?

Shenzhen Hailian Electronics (HLLED) is a high-tech company established in 2007, specializing in the LED lighting industry. The company offers over 500 standard LED aluminum profiles, including mini-sized (under 12mm), V-shaped corners, double-sided, waterproof, and custom shapes, suitable for various installation scenarios such as walls, ceilings, and recessed installations.

For this HL-BAPL067-F 8 mm profile light product, we offer custom procurement, OEM/ODM services.

6063-T5 aluminum alloys dissipate heat 30% faster than industry standards, extending LED strip lifespan by up to 50%

Compatible with 12mm–15mm double-row LED strips, PC opal/translucent diffusers, and IP67 end caps for dust/moisture resistance.

Pre-installed channels support tool-free installation and protect light strips from physical impact—suitable for various lighting scenarios, such as museums, offices, and outdoor walkways.

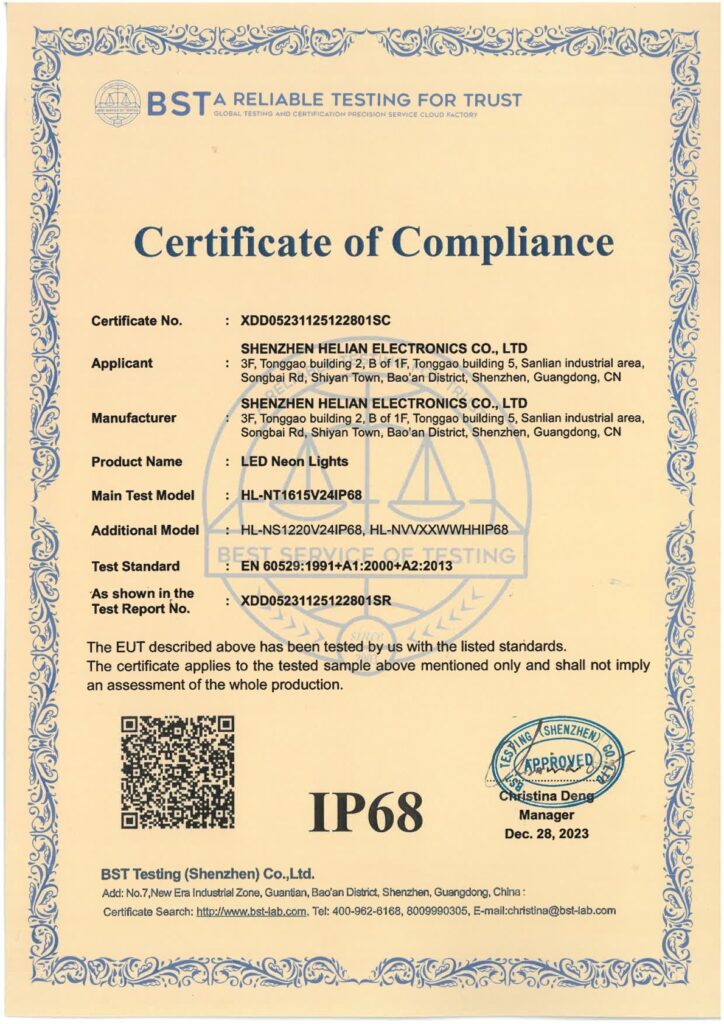

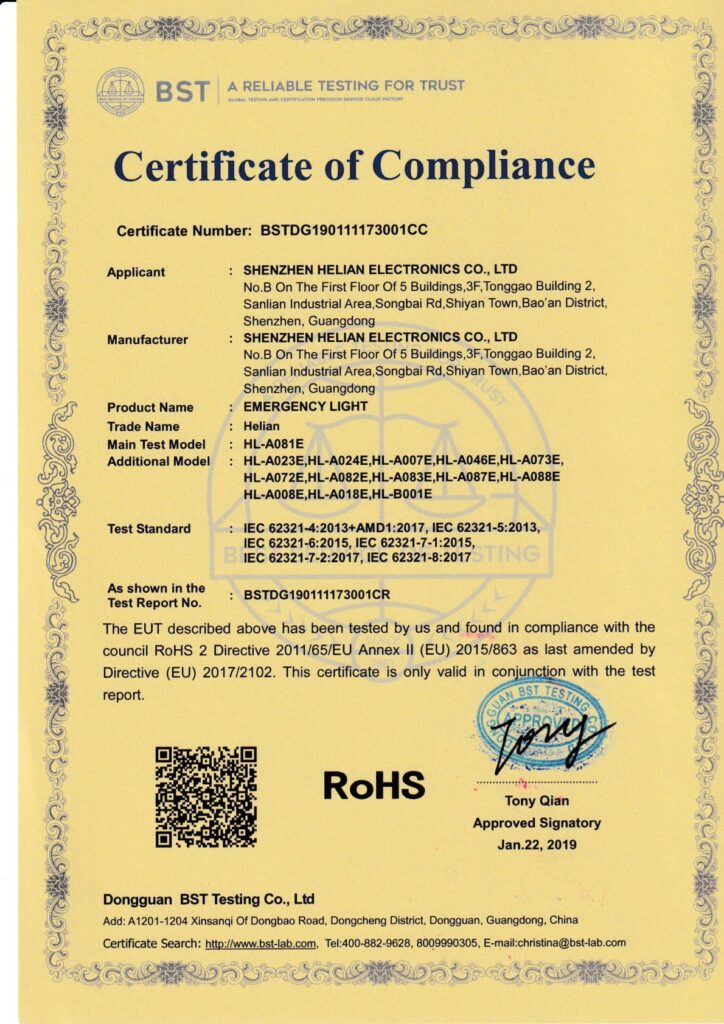

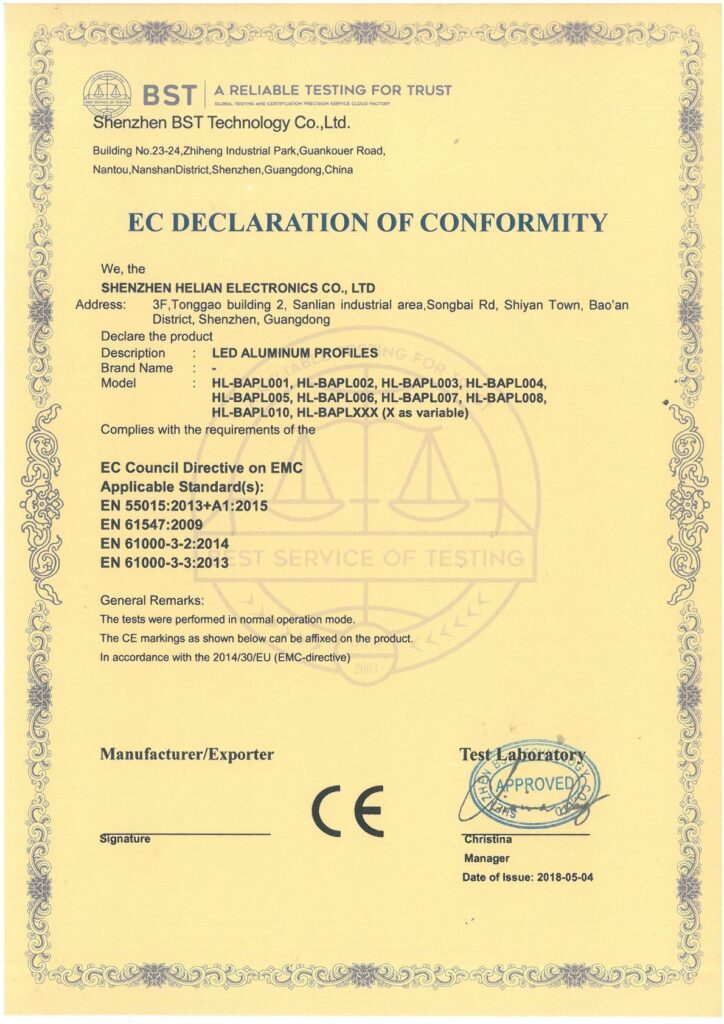

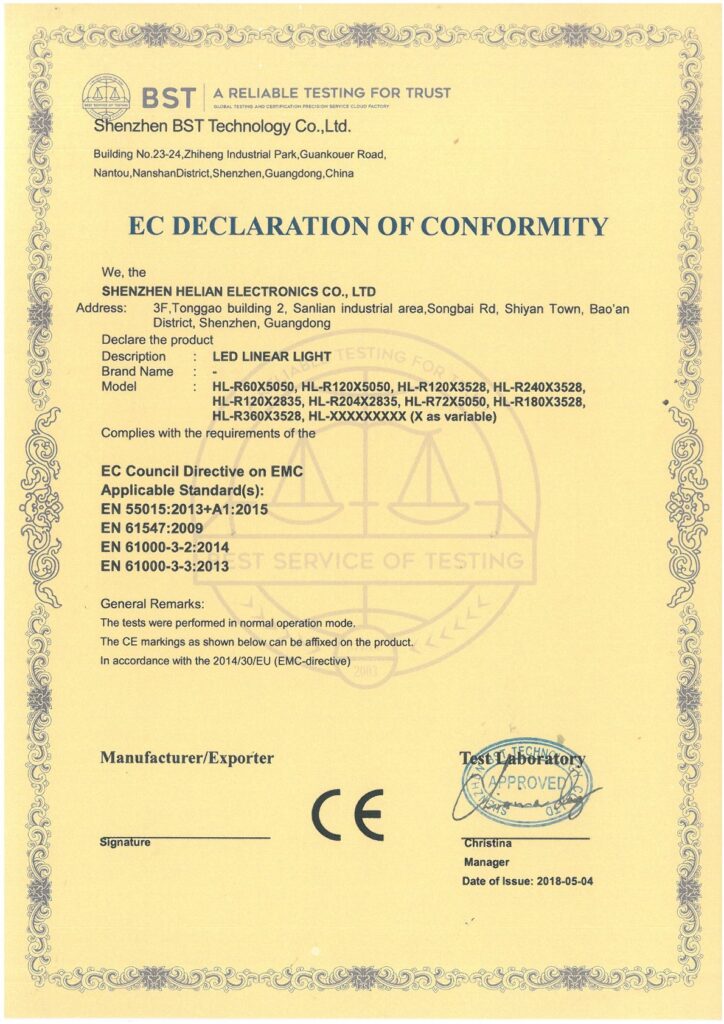

Certificates

Wholesale/purchasing process for 8 mm profile light

Consult customer service

Provide 24-hour online customer service.

Confirm demand

Please sync the model/sku/quantity/customization requirements of the products you need to customer service, we will solve all the problems for you.

Order

After determining your needs, our customer service staff will assist you in placing your order, so there is absolutely nothing to worry about.

Provide delivery

We have the appropriate shipping channels, but of course you can also specify your own shipping service.

Delivery

You will soon receive the products you have purchased.

Checkout

Support T/T, Paypal, Credit Card, Banker’s Acceptance, etc.

Unlock Endless Possibilities with LED Profiles

A comprehensive product range provides lighting solutions for all kinds of scenarios.