Observação: Para garantir a precisão, este artigo segue o processo de criação e revisão de conteúdo da A equipe de especialistas da Helian.

Os diodos emissores de luz (LEDs) mudaram a forma como iluminamos nossas casas porque são eficientes em termos de energia, duradouros e flexíveis. Mas pode ser difícil saber que tipos de LEDs existem, quais são suas especificações e como utilizá-los da melhor forma. A seguir, respondemos às perguntas mais comuns sobre LEDs com respostas claras e confiáveis baseadas nos padrões do setor (como IESNA) e em dados reais.

Quais são os principais tipos de luzes de LED?

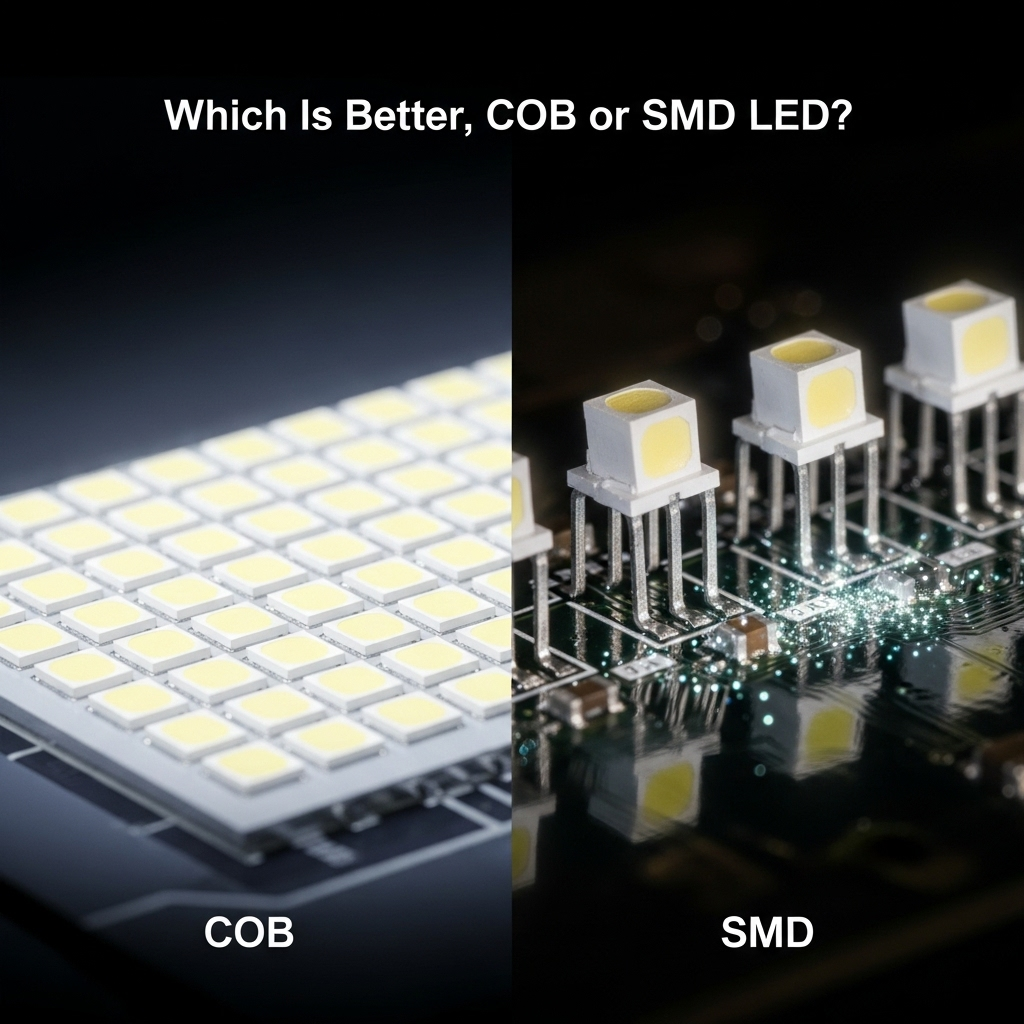

“Tipos de lâmpadas LED” pode significar várias coisas, incluindo embalagem, uso ou padrão de feixe. Mas a maneira mais comum de agrupá-las é pela tecnologia de empacotamento estrutural, que desempenha um papel importante no desempenho, no custo e nos casos de uso. Existem três tipos principais:

LEDs com tecnologia COB (Chip-on-Board)

Os COBs colocam muitos chips de LED diretamente em um único substrato, como uma cerâmica ou uma placa de circuito impresso com núcleo de metal, de modo que não há necessidade de gabinetes separados. Os padrões do setor permitem que os COBs façam o seguinte:

- Alta densidade de lúmens (excelente para fins que exigem muita luz).

- Dispersão uniforme da luz com poucos pontos críticos (muito importante para a iluminação comercial).

- Melhor dissipação de calor (demonstrada por testes térmicos), o que os torna bons para luzes de estádios, postes de iluminação pública e holofotes.

LEDs para dispositivos montados em superfície (SMDs)

Os SMDs são chips individuais colados em PCBs sem cabos. Essa é a variedade mais popular para uso diário. De acordo com as regras da IESNA, seus pontos fortes incluem o tamanho pequeno (2835, 3528 e 5050 são tamanhos comuns) e sua capacidade de ser projetado de várias maneiras (por exemplo, fitas de LED curvas).

- Custo-benefício (fabricado em grandes quantidades para lâmpadas domésticas, luzes de carros e displays).

- Eficiência moderada (encontra uma boa combinação entre brilho e custo para uso residencial e comercial).

LEDs em embalagem dupla em linha (DIP)

Os DIPs são a forma mais antiga de embalagem. Eles têm um invólucro de plástico/epóxi com dois fios que se destacam. No entanto, são úteis para aplicações de nicho, como painéis de instrumentos de veículos e indicações de aparelhos, mesmo que sejam menos comuns para iluminação primária.

- Resistente (pode suportar vibrações e trabalhar com sistemas mais antigos).

Qual é o melhor LED, COB ou SMD?

Não existe uma solução única que funcione para todos; sua opção dependerá de como você deseja usá-la, de quanto dinheiro você tem e de quão bem ela precisa funcionar. Com base em testes no campo e no mundo real, aqui está uma comparação confiável:

| Dimensão de comparação | Cenários de aplicativos principais | Eficiência energética | Qualidade da saída de luz | Dissipação de calor e vida útil | Custo inicial | Flexibilidade de design | Dificuldade e custo de manutenção | Densidade do lúmen (potencial de brilho) | Limitações potenciais | Recomendação final |

| LED COB (Chip-on-Board) | 1. Cenários comerciais de alto brilho (por exemplo, estádios, holofotes externos, iluminação principal em grandes shopping centers) 2. Cenários sensíveis à uniformidade da luz (galerias de arte, vitrines de varejo de joias/roupas) | 24% mais eficiente do que os LEDs SMD padrão em cenários com Índice de Renderização de Cores (CRI) de mais de 90 (dados dos laboratórios do setor de LEDs) | Sem pontos críticos, distribuição uniforme de luz (desvio ≤ 5%), adequado para cenários que exigem alta reprodução de cores (por exemplo, iluminação de obras de arte) | Excelente dissipação de calor com substratos de cerâmica/metal, reduzindo a depreciação do lúmen; a vida útil é 10-15% mais longa do que a dos LEDs SMD de baixa qualidade (média de 50.000 a 60.000 horas) | 30-50% custo inicial de compra mais alto do que os LEDs SMD com o mesmo brilho (devido à tecnologia de integração de vários chips) | Design integrado com grande volume; não adequado para luminárias curvas/estreitas (por exemplo, fitas de luz curvas, microdispositivos) | Alta integração de chips; substituição geral necessária para falhas parciais, o que leva a altos custos de manutenção | Alta (200-250 lúmens/W); é possível obter alta potência por conta de uma única lâmpada (10-50W) sem emendar várias contas de lâmpada | 1. Baixa flexibilidade de design; incompatível com luminárias de formato micro/especial2. Alto investimento inicial; baixo custo-benefício para iluminação de pequenas áreas | Escolha prioritária para cenários comerciais/profissionais que exigem alto brilho, efeito de luz uniforme e longa vida útil (por exemplo, estádios, exposições de arte) |

| LED SMD (Surface-Mounted Device, dispositivo montado na superfície) | 1. Iluminação residencial (lâmpadas domésticas, luzes de teto, downlights)2. Cenários decorativos de baixo custo (tiras flexíveis de LED, luzes de Natal)3. Iluminação de fundo para pequenos dispositivos (painéis de instrumentos automotivos, displays eletrônicos) | Atende aos padrões de eficiência em cenários regulares (120-150 lúmens/W); a eficiência é um pouco menor do que a do COB em cenários de CRI 90+ | A uniformidade da luz depende do espaçamento entre os chips; podem ocorrer pontos quentes se o espaçamento for irregular (o desvio pode exceder 10%), mas pode atender às necessidades de cenários de iluminação regulares | Dissipação média de calor com substratos plásticos; a vida útil de produtos de baixa qualidade é de cerca de 40.000 a 50.000 horas; os LEDs SMD com substratos de cerâmica (por exemplo, modelo 3535) têm dissipação de calor próxima à do COB | Vantagem significativa de custo; o preço de compra em massa é 30-50% menor do que o COB, adequado para cenários sensíveis ao orçamento | Ultrafino (0,8 a 1,2 mm de espessura) e miniaturizado, com suporte a PCBs flexíveis (por exemplo, fitas de luz curvas) para luminárias com formatos complexos | Os chips individuais podem ser destacados e substituídos independentemente (ferramenta: pistola de calor), resultando em baixos custos de manutenção (somente os chips defeituosos precisam ser substituídos) | Média (120-180 lúmens/W); baixa potência por filete único de lâmpada (0,2-1W); é necessária a emenda de vários conjuntos de filetes de lâmpada para cenários de alto brilho | 1. A emenda de vários grânulos de lâmpada é necessária para cenários de alto brilho, o que pode aumentar o volume da luminária2. Qualidade desigual dos chips em produtos de baixo custo, propensos a uma depreciação desigual do lúmen | Escolha prioritária para iluminação residencial, decoração de baixo custo e cenários com necessidades de design flexíveis (por exemplo, fitas de luz domésticas, pequenos dispositivos eletrônicos) |

A decisão final: Se você precisar de algo para uso comercial ou com alto brilho, escolha COB. Se precisar de algo para uso doméstico, com um orçamento limitado ou que possa ser alterado, escolha SMD.

O que é LED tipo 3?

A Illuminating Engineering Society of North America (IESNA), o principal grupo que define os padrões de design de iluminação, define “LED Tipo 3” como um tipo de distribuição de feixe, não um tipo de embalagem.

Informações importantes sobre os LEDs do tipo 3:

- Padrão do feixe: Ele tem formato oval e uma extensão lateral de 40°, o que significa que é menor que o Tipo IV e mais largo que o Tipo II.

- Projeção de luz: Envia 60-70% de luz para frente e muito pouca luz para trás (reduz o ofuscamento).

- Melhores usos:

Estradas com 4 a 6 faixas de tráfego.

Passarelas e estacionamentos.

Luminárias para a parte externa dos edifícios que ficam na parede.

A IESNA também especifica o Tipo I (estreito, para calçadas), o Tipo IV (amplo, para grandes estacionamentos) e o Tipo V (circular, para espaços abertos como parques).

Quais tipos de luzes de LED são melhores?

“Melhor” depende do que você precisa; nenhum tipo é melhor do que todos os outros em todas as situações. Aqui está um paradigma de tomada de decisão baseado nas necessidades básicas:

| Necessidade básica | Tipo de LED recomendado | Justificativa |

| Alto brilho | LED COB | Proporciona de 150 a 200 lúmens por watt, o que é mais alto do que os LEDs SMD (120 a 150 lúmens por watt) |

| Baixo custo | LED SMD (por exemplo, modelos 2835, 3528) | Produção em massa em grandes quantidades; o custo inicial é 30%-40% inferior ao dos LEDs COB |

| Indicadores simples | LED DIP | Estrutura robusta, baixo consumo de energia e compatível com sistemas de circuitos mais antigos |

| Aplicações decorativas ou curvas | LED SMD (tiras de luz flexíveis) | Apresenta PCBs finas e flexíveis que se adaptam a superfícies curvas (por exemplo, iluminação de cobertura) |

| Durabilidade em ambientes externos | LED COB (com substrato de cerâmica) | Com ampla classificação IP65+; resistente a flutuações de temperatura e mudanças de umidade |

O que significa LED 2835?

O tamanho da embalagem em milímetros é 2,8 mm (comprimento) x 3,5 mm (largura) × 0,8 mm (altura), que é o que “2835” significa LEDs SMD. É uma das variedades mais comuns de SMDs de potência média usados para iluminação interna em todo o mundo.

Recursos mais importantes do 2835 LEDs:

- Potência: Cada chip geralmente usa de 0,2 W a 0,5 W (mais do que 3528 LEDs, mas menos do que 5050).

- Brilho: Os LEDs 2835 com uma tensão direta de 3V emitem de 70 a 75 lúmens, o que é suficiente para uso doméstico.

- Opções de cores:

Branco (branco quente de 2700K a branco frio de 6500K).

Colorido (vermelho, verde, azul - para iluminação decorativa). - Aplicativos:

Downlights internos e luzes de painel.

Lâmpadas residenciais (A19, PAR38).

Iluminação sob o gabinete e fitas de luz.

Por que a 2835? Ele atinge uma boa combinação entre tamanho, brilho e preço acessível, o que o torna um “ponto ideal” para as necessidades diárias de iluminação.