Note: To ensure and accuracy, this article follows the content creation and review process of the Helian Expert Team.

what’s the LED corner profile?

LED strip corner profiles are used to mount LED strips and achieve seamless light transitions at corners.

Features

- Protective Light Strip: Typically made of aluminum, such as 6063 aluminum alloy, it provides physical protection for LED light strips against impacts, scratches, and other damage. It also effectively dissipates heat, extending the lifespan of the LED light strip.

- Easy Installation: Usually comes with mounting brackets, end caps, and other accessories. Can be installed at corners using screws or adhesive, offering simple operation for quick installation and replacement.

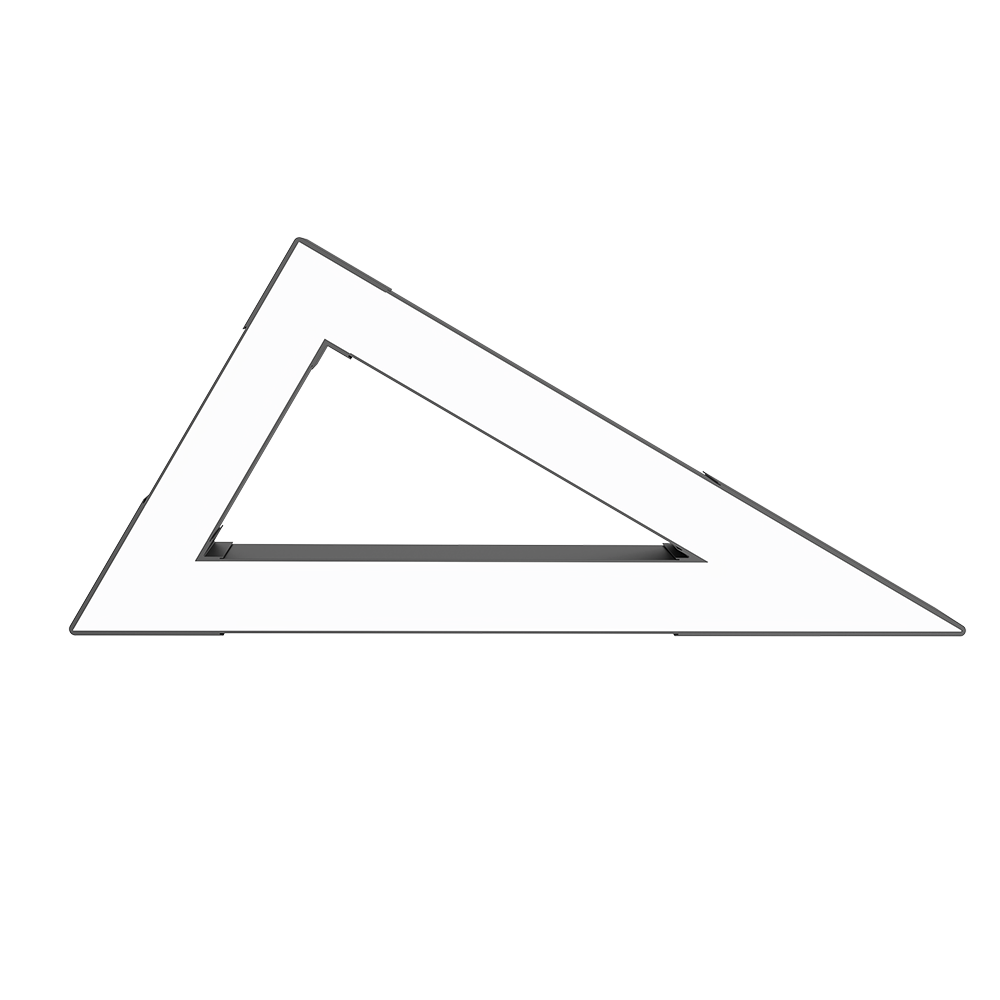

- Aesthetic and Practical: Available in various shapes and surface finishes, such as 90° right angles, 45° beveled edges, and rounded corners. Meets diverse decorative needs, creating softer, more uniform lighting effects while minimizing glare.

LED Corner Lighting Solution

When dealing with corners in LED strip installations, there are several solutions, each with a different purpose. The term “corner profile” can refer to two main things: an aluminum extrusion that houses and diffuses light around a corner, or a small connector that electrically joins two strips at an angle.

Here is a quick comparison of the common solutions:

| Solution Type | Primary Use | Key Features | Best For |

| Recessed/Coved Extrusions | Housing strips in corners (e.g., wall-ceiling) | Aluminum channel with diffuser; provides 45° angled light | Professional, built-in linear lighting in architecture. |

| Flexible Aluminum Profiles | Housing strips on curved surfaces or wide angles | Bendable aluminum; includes diffuser, end caps, brackets | Curved walls, furniture, or corners > 90°. |

| 90° Corner Connectors | Electrically connecting two strips at a right angle | Small plastic L-shaped piece; solderless connection | Creating a clean electrical turn without housing. |

| Folding the Strip | Bending the strip itself at a corner | Manual folding of flexible strip; can damage LEDs if done incorrectly | Quick, low-cost solutions where strips are hidden. |

| Jump Wire Connectors | Connecting strips at non-standard angles | Flexible wire between connectors; allows for custom angles | Irregular corners or situations where strips are not aligned. |

Understanding Your Options in Detail

1. Recessed Aluminum Extrusions (for a built-in look)

This is what manufacturers like Helian refer to as a “Corner” profile. It’s an aluminum channel designed to be installed where two surfaces meet (like a wall and ceiling). The LED strip sits inside, and a diffuser spreads the light at a specific angle (e.g., 45°). These create a very professional, seamless line of light.

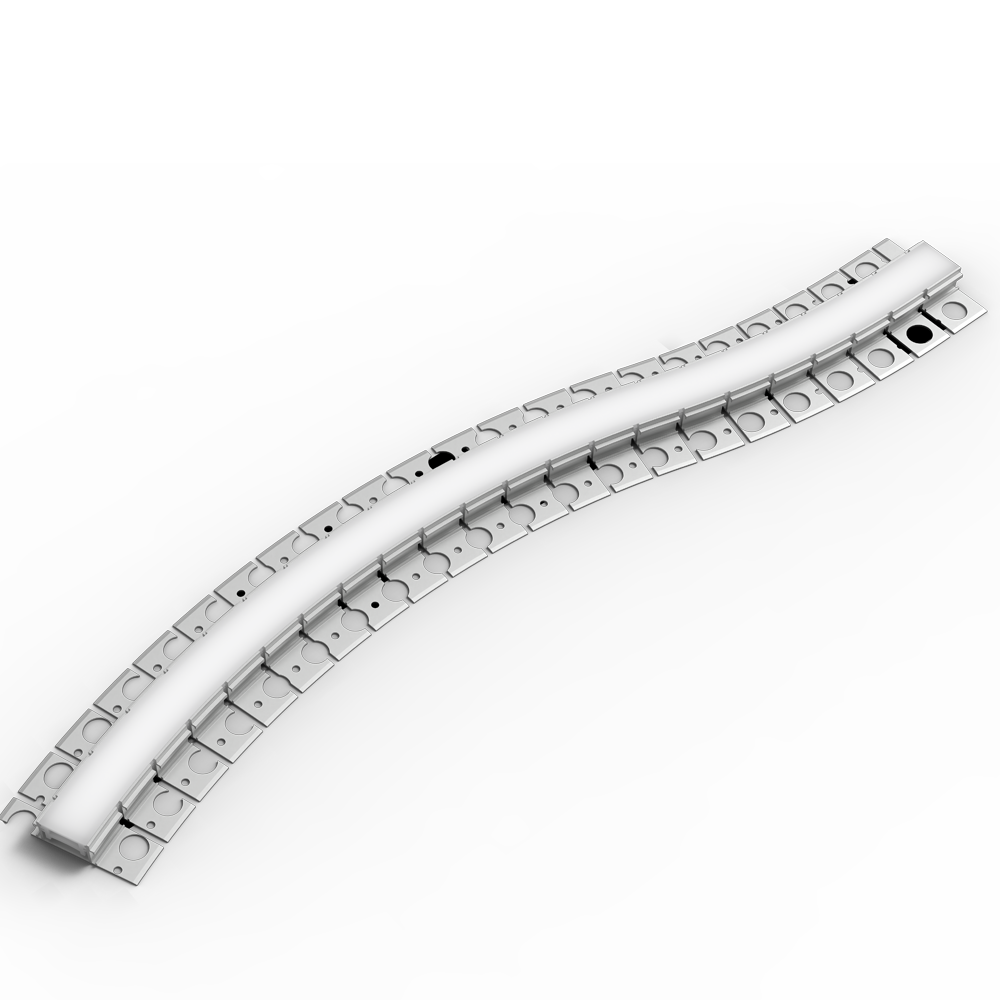

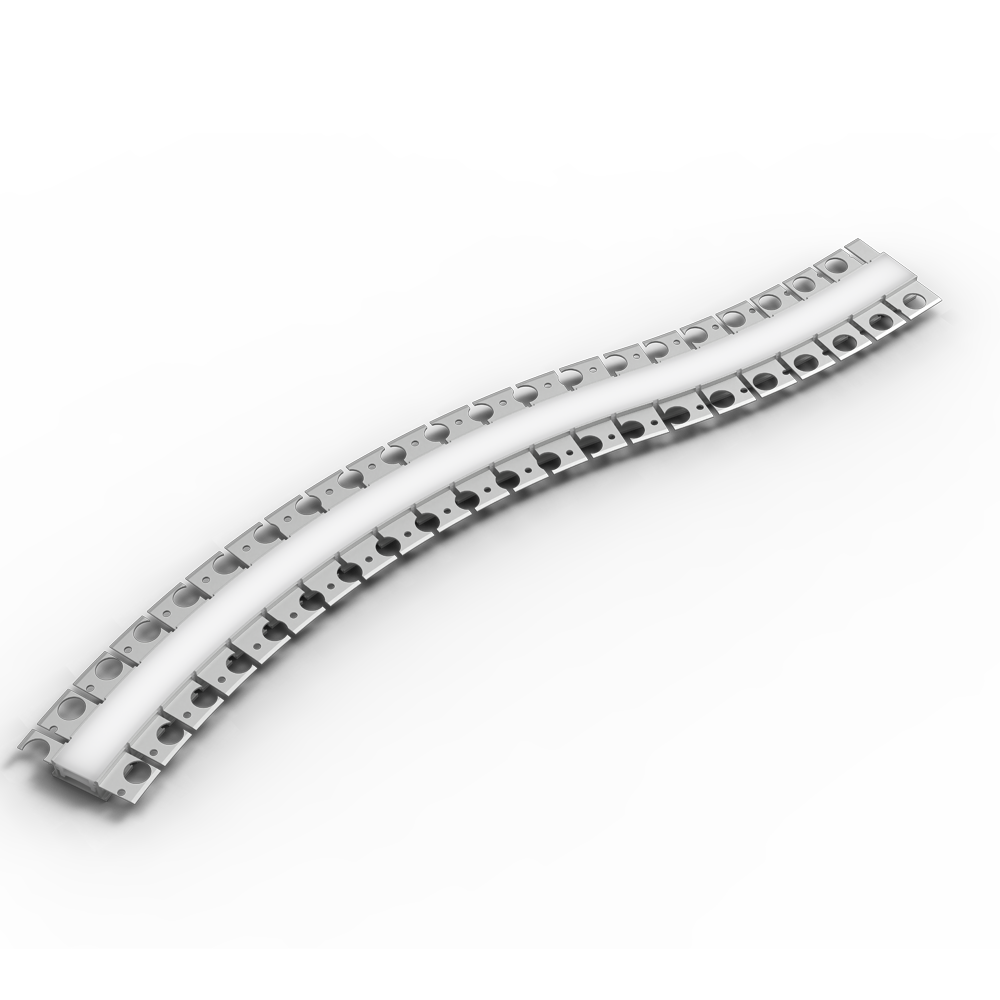

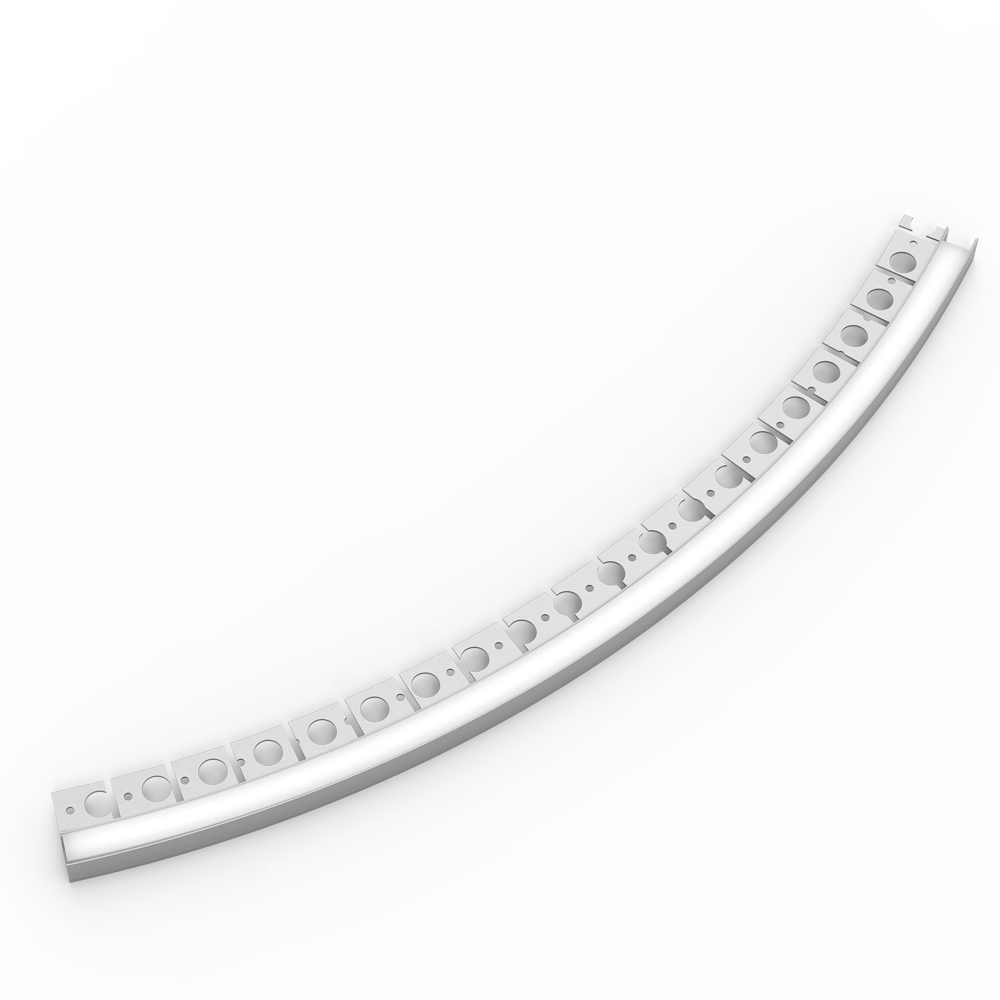

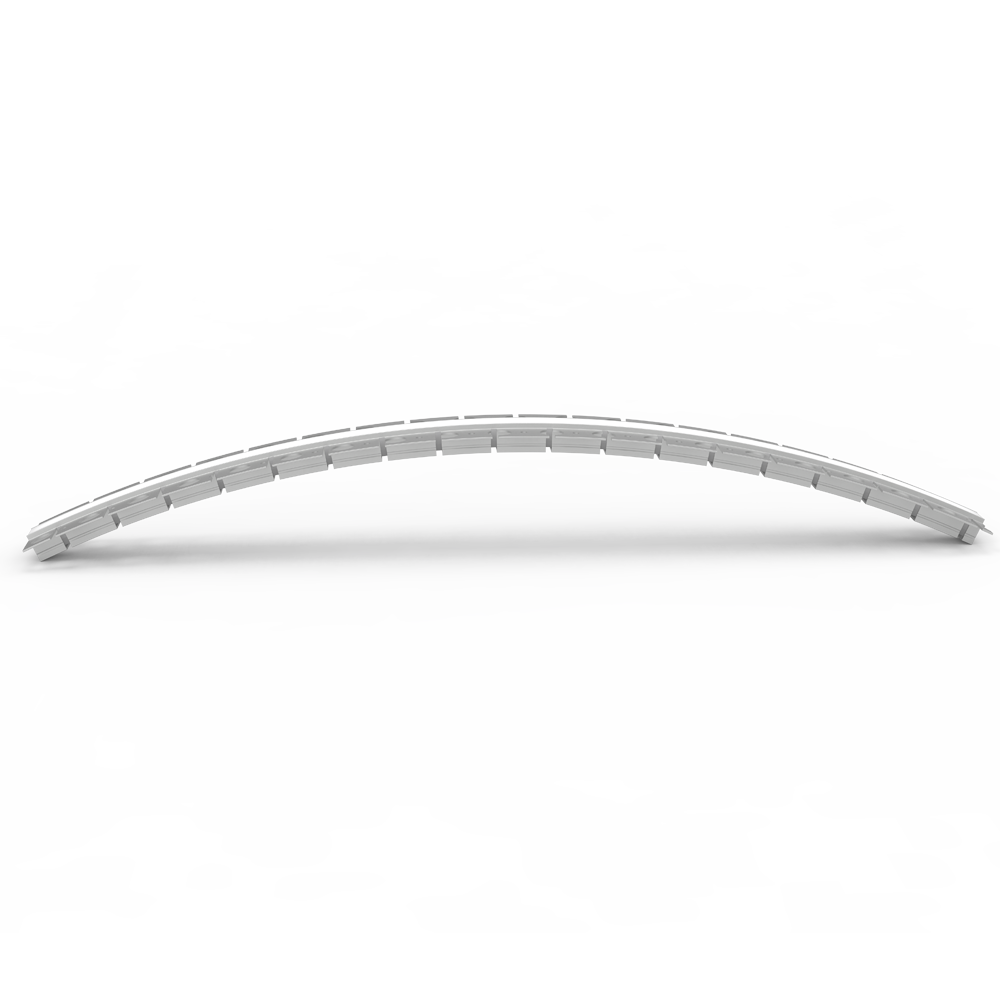

2. Flexible Aluminum Profiles (for curves and wide angles)

If your corner is rounded or the angle is greater than 90 degrees, a standard rigid profile won’t work. Flexible profiles are made of bendable aluminum and can handle curves with a radius as small as 4cm. They include a diffuser and mounting hardware, making them ideal for curved walls, archways, or circular furniture.

3. 90° Corner Connectors (for electrical connection only)

These are not profiles but small plastic connectors. You cut your LED strip at the corner, insert the ends into the two sides of the L-shaped connector, and it creates both the electrical connection and the physical turn. This is a clean solution but leaves the strip exposed unless you also use a covering profile.

4. DIY Methods: Folding and Jump Wires

- Folding: You can carefully fold a flexible LED strip at the copper cut points to make a 90° turn. However, this risks damaging the LEDs or circuitry if done at a point with an LED.

- Jump Wires: For irregular angles, you can use a flexible “jumper” cable with connectors at each end. This provides the most flexibility but requires more precise cutting and connecting.

How to Choose and Install

To pick the right solution, consider:

- The Desired Finish: For a sleek, architectural look with diffused light, choose an aluminum extrusion.

- The Corner Angle: Use a 90° connector for standard right angles. For curves or wide angles, use a flexible profile.

- Installation Location: Recessed profiles are for built-in applications, while surface-mounted profiles or simple connectors work for add-on projects.

Installation Tips:

- Measure and Plan: Dry-fit all components before making any permanent cuts or adhesions.

- Mind the Diffuser: Many aluminum profiles come with a milky diffuser cover that blocks only about 10% of light while making it perfectly even.

- Secure Properly: Use the included mounting clips or brackets. For a permanent hold on smooth surfaces, high-quality double-sided tape or screws work best.

- Avoid Light Leaks: At the joint where two straight profiles meet at a corner, you might see a small gap. Specialized corner sealing members or careful alignment can solve this.

LED strip corner profile is a dedicated accessory for LED strip installation at corners. It offers protection, heat dissipation, seamless transition and anti-glare functions, with types like 90° right angle, 45° bevel and rounded corner, widely used in home, commercial display and advertising sign scenarios.

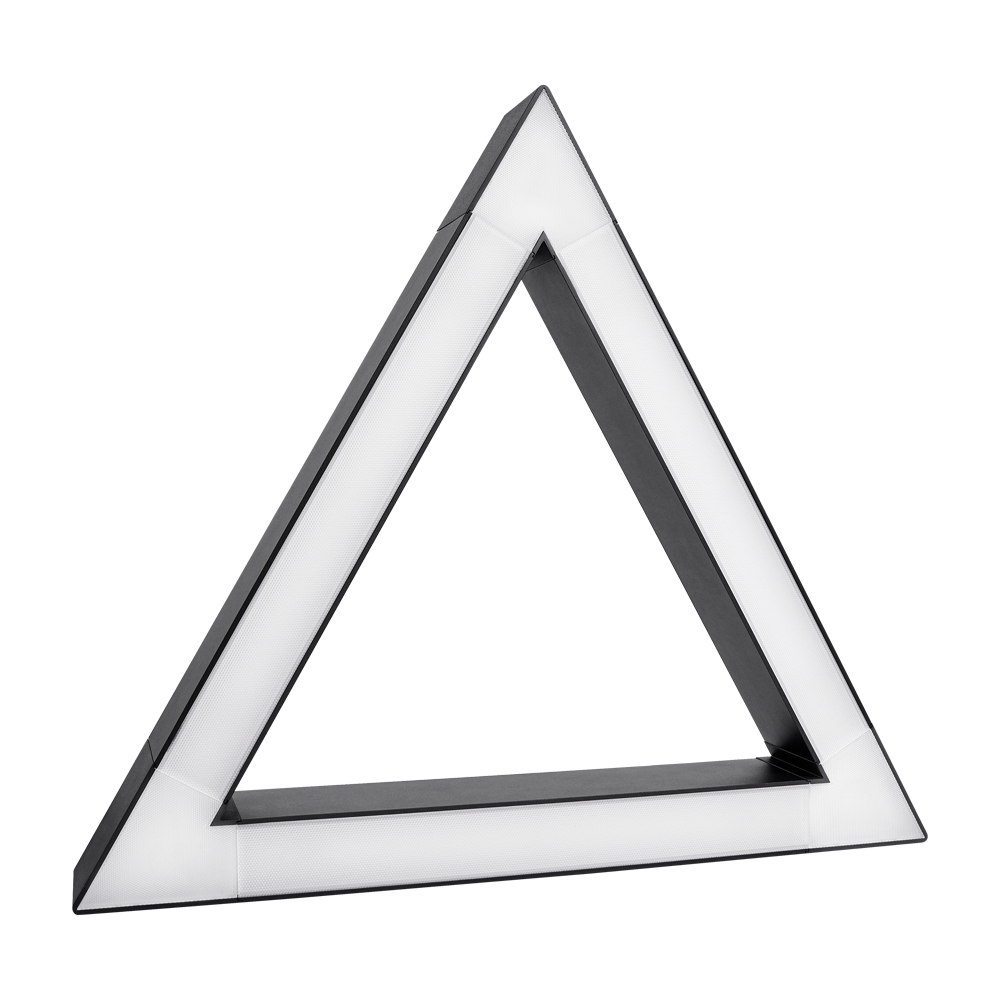

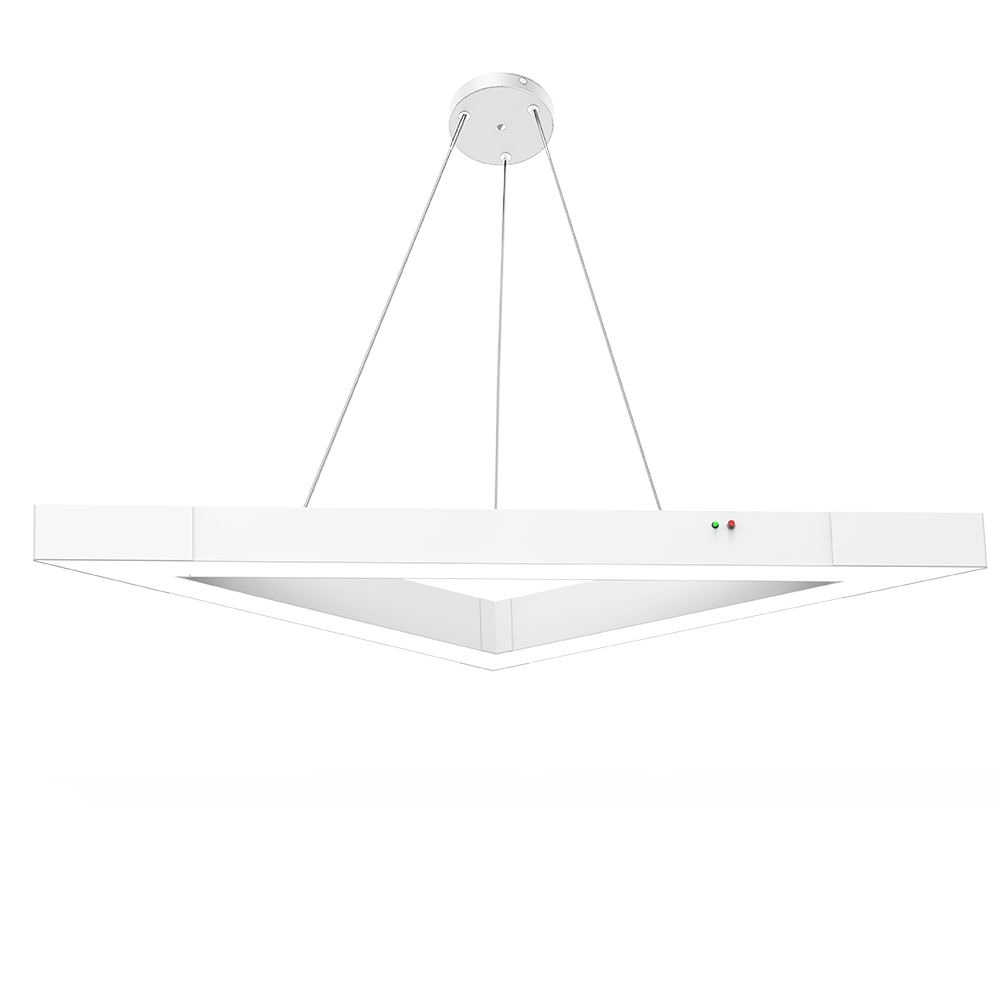

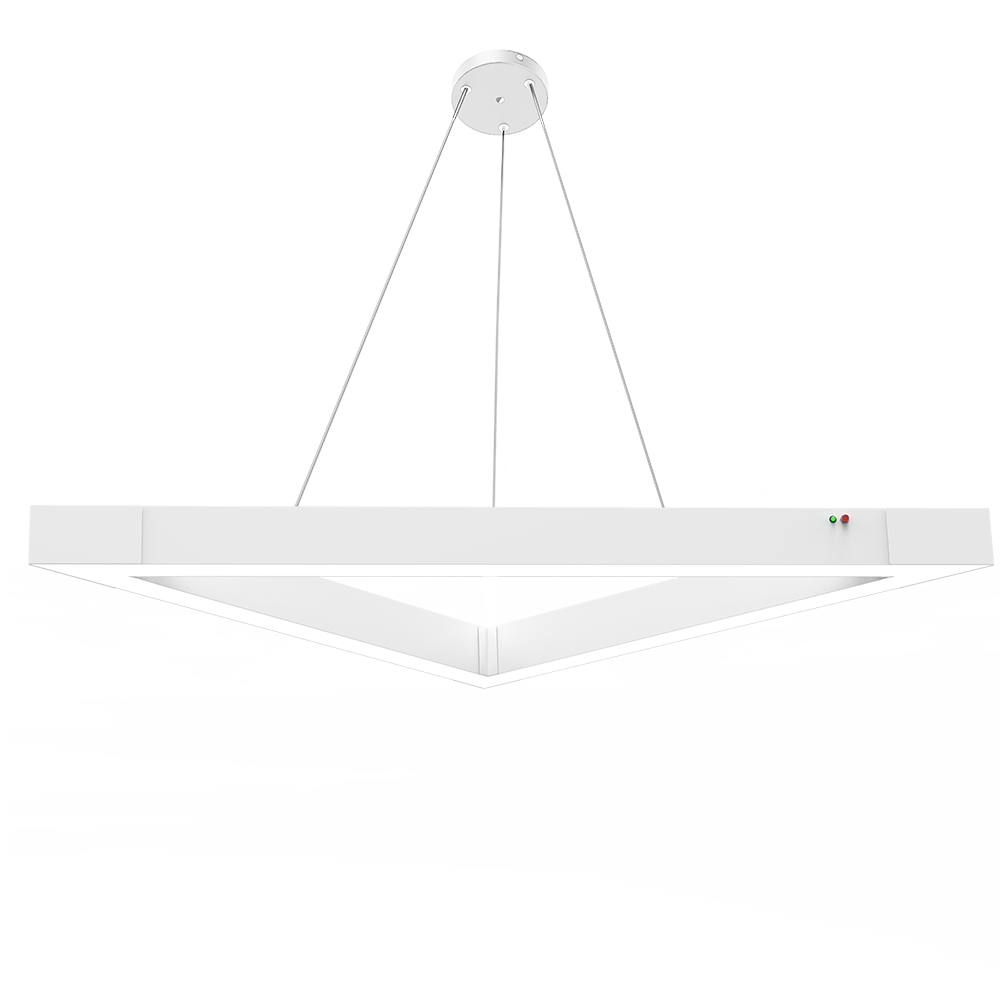

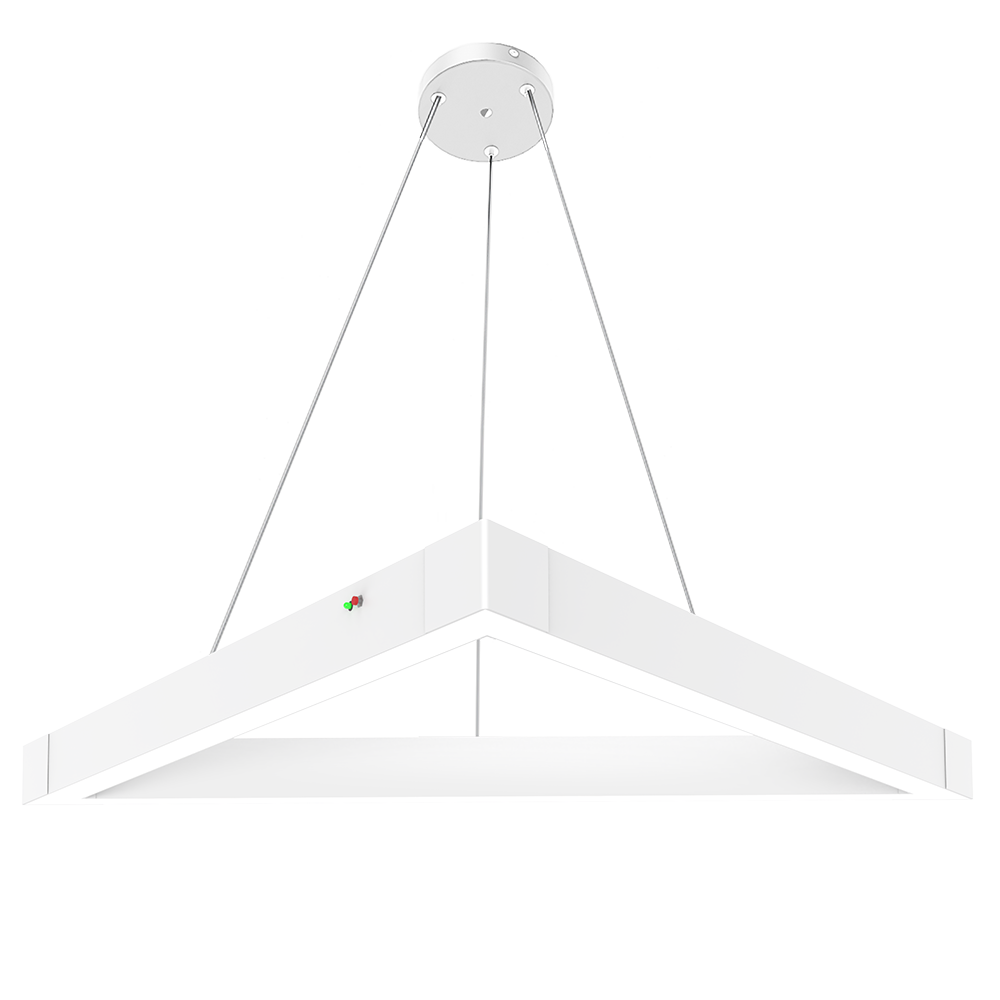

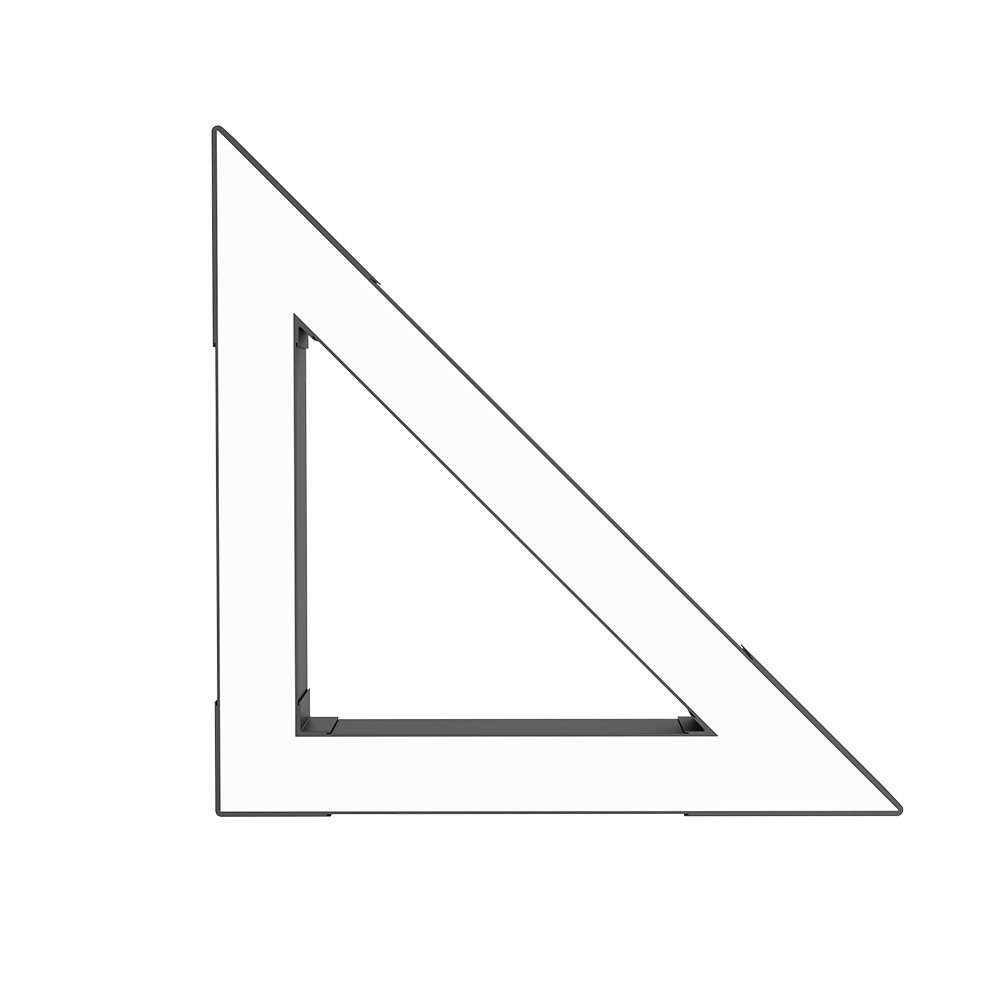

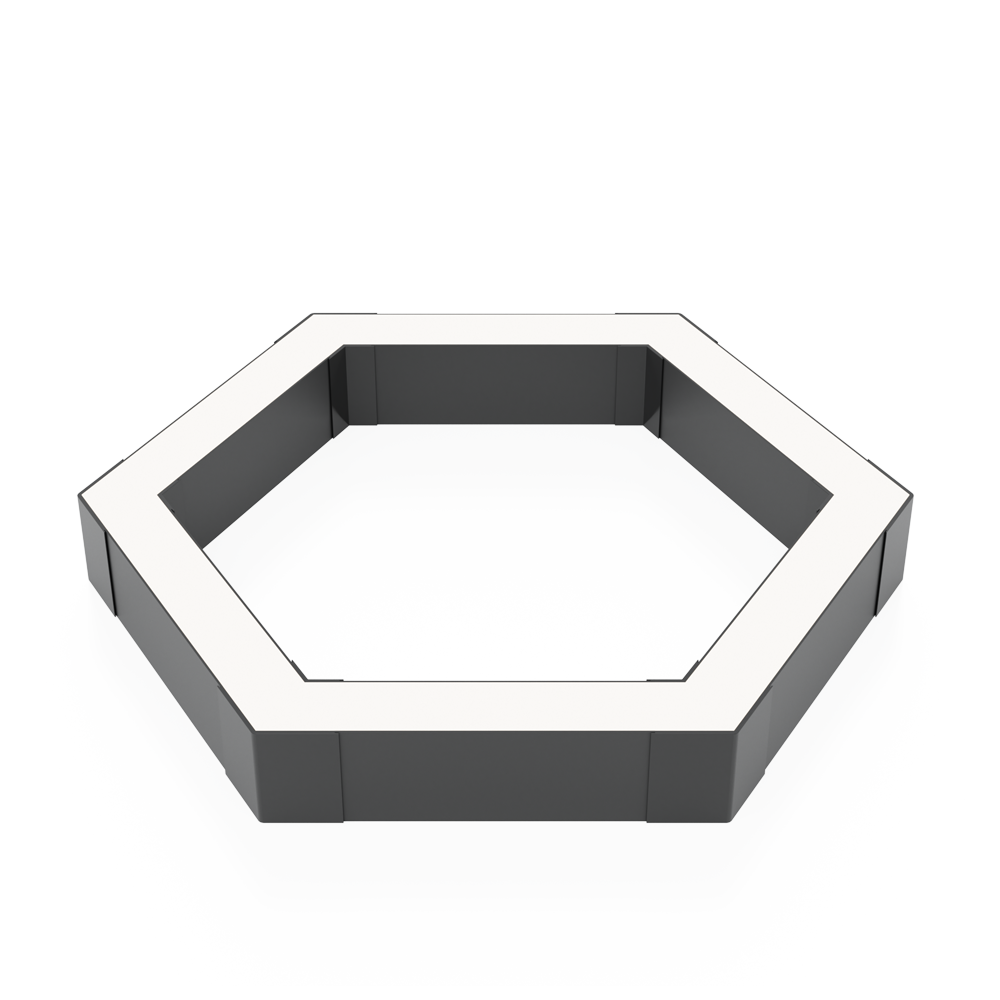

![[Smart Puzzle Series] Creative LED ceiling light, free splicing installation, lighting design DIY, HL-PB5075A-A06](https://hlled.com/wp-content/uploads/2024/07/Smart-Puzzle-Series-Creative-LED-ceiling-light-free-splicing-installation-lighting-design-DIY-HL-PB5075A-A06.jpg)