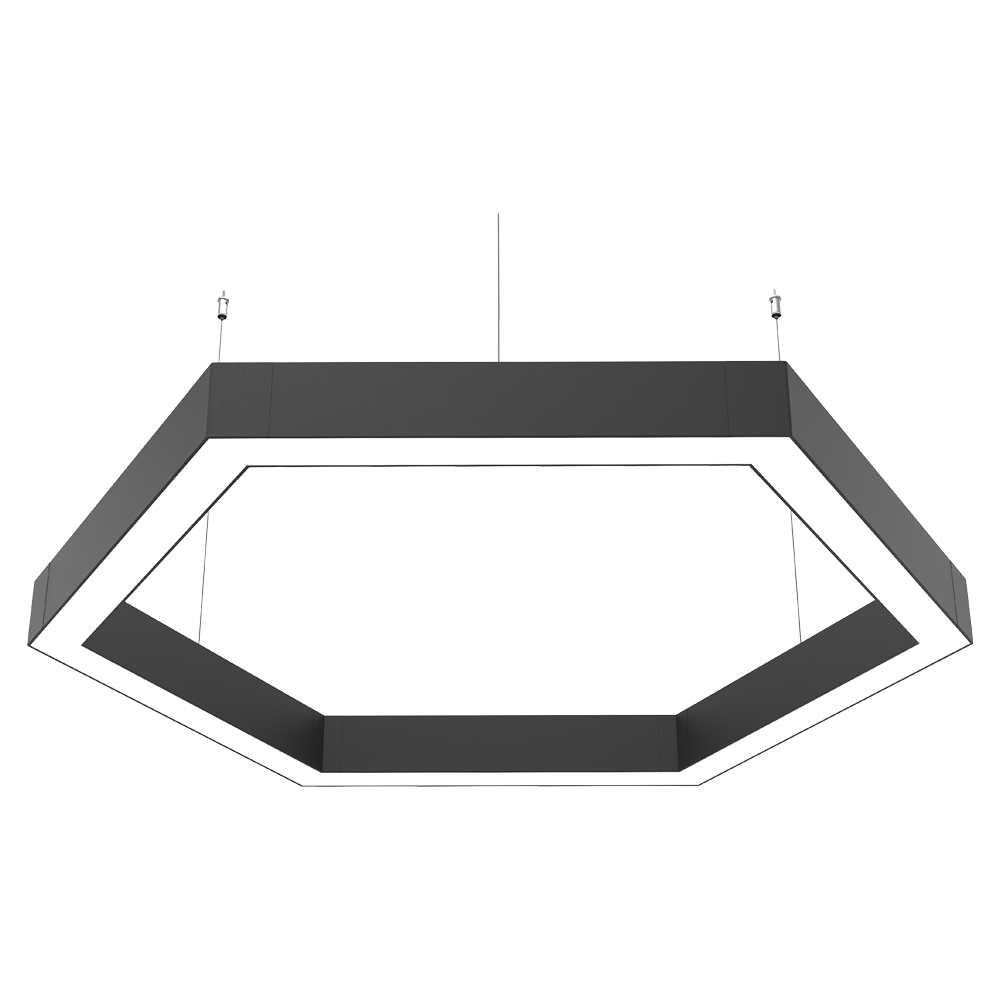

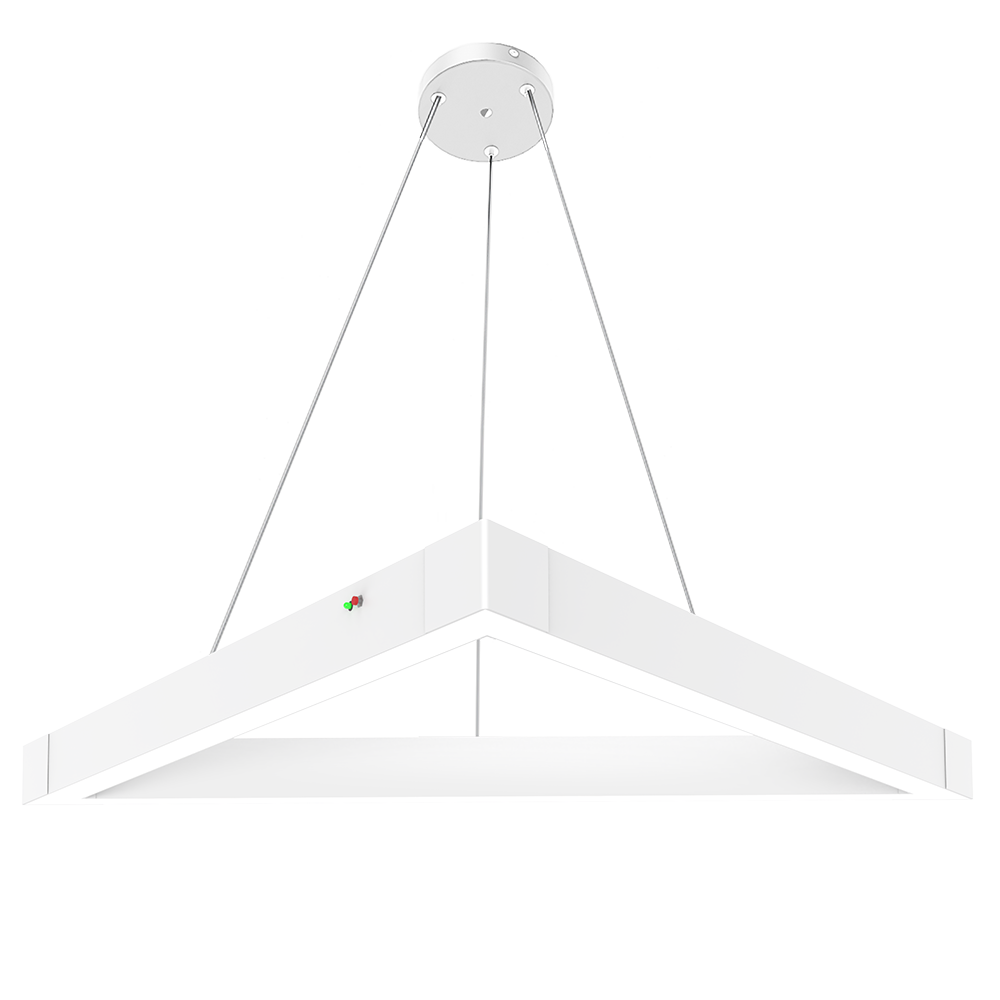

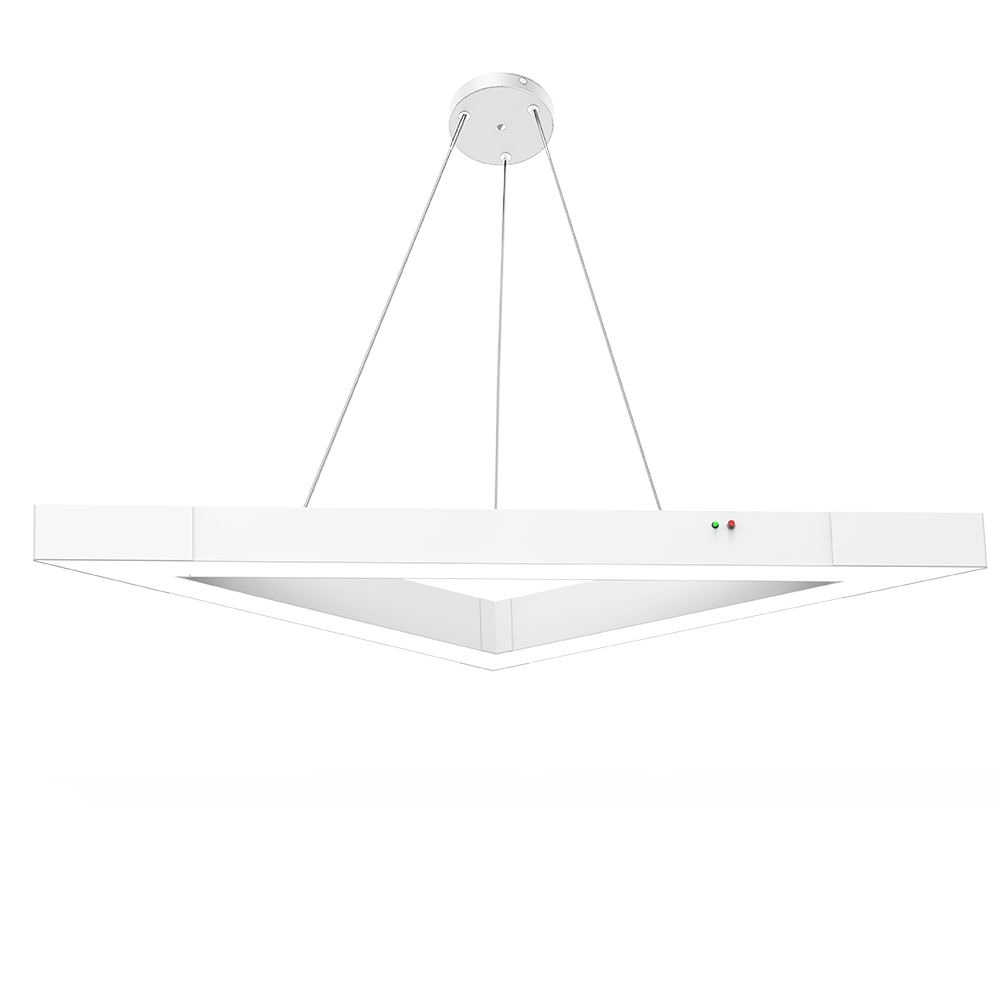

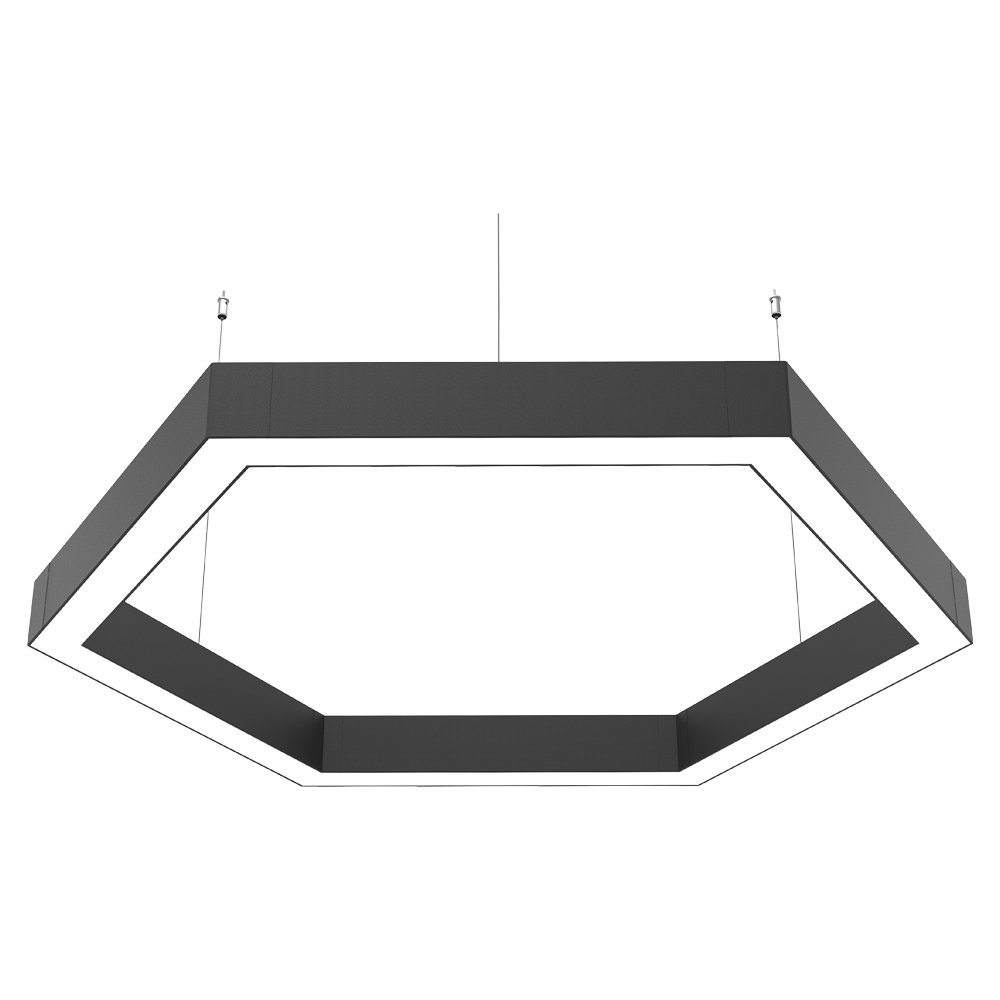

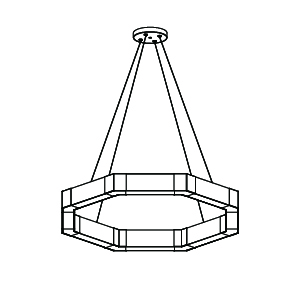

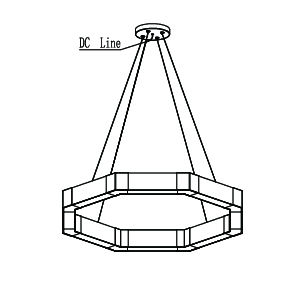

High-quality energy-efficient Modular Octagon Lighting for Offices and Conference Rooms

Key parameters:| Model: | HL-PB5075A-E81 | Power: | 100W |

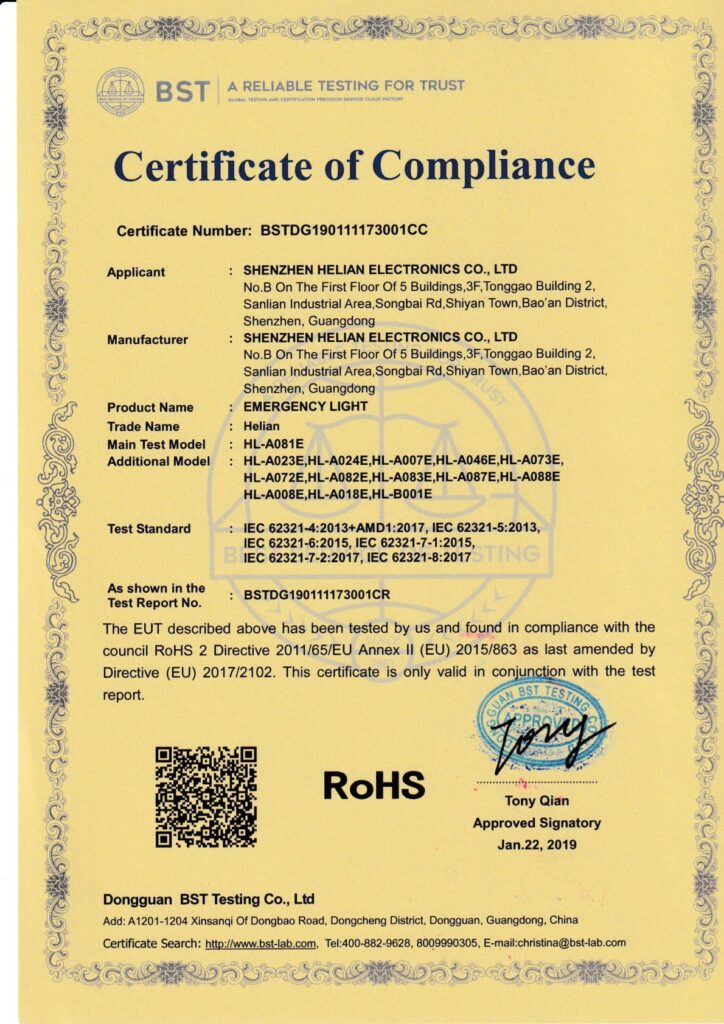

| Color Temperature: | 2700-6500 K | Certification: | CE,RoHS |

| Product Dimension: | 1200mm*1108mm | CRI: | Ra80 |

Technical Specifications

| Model | HL-PB5075A-E81 | Material | AL6063+PC/PMMA |

| Net Weight | 7.3kg/PCS | Gross Weight | 8.2kg/PCS |

| Package Size | 840mm*460mm*100mm | Product Dimension | 1200mm*1108mm |

| Luminous Flux | 10000lm±10%(@4000K) | PowerPower | 100W |

| Color Temperature | 2700-6500 K | Beam Angle | 110°-120° |

| Voltage | AC200-240V | Working Temperature | -20℃ ~ +50℃ |

| CRI | Ra80 | Certification | CE,RoHS |

| IP Degree | IP20 | OEM/ODM | Support |

Downloads

HL-PB5075A-E81 LED Profile Details

Features of HL-PB5075A-E81

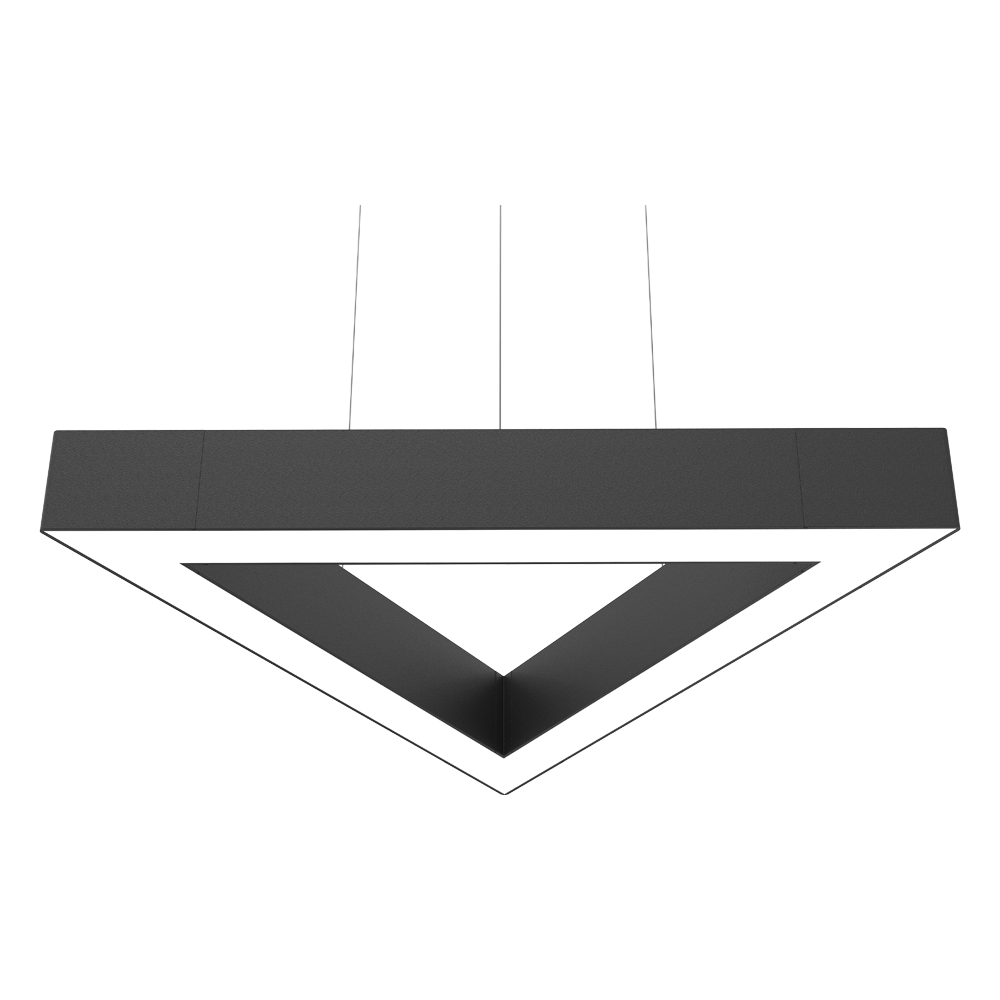

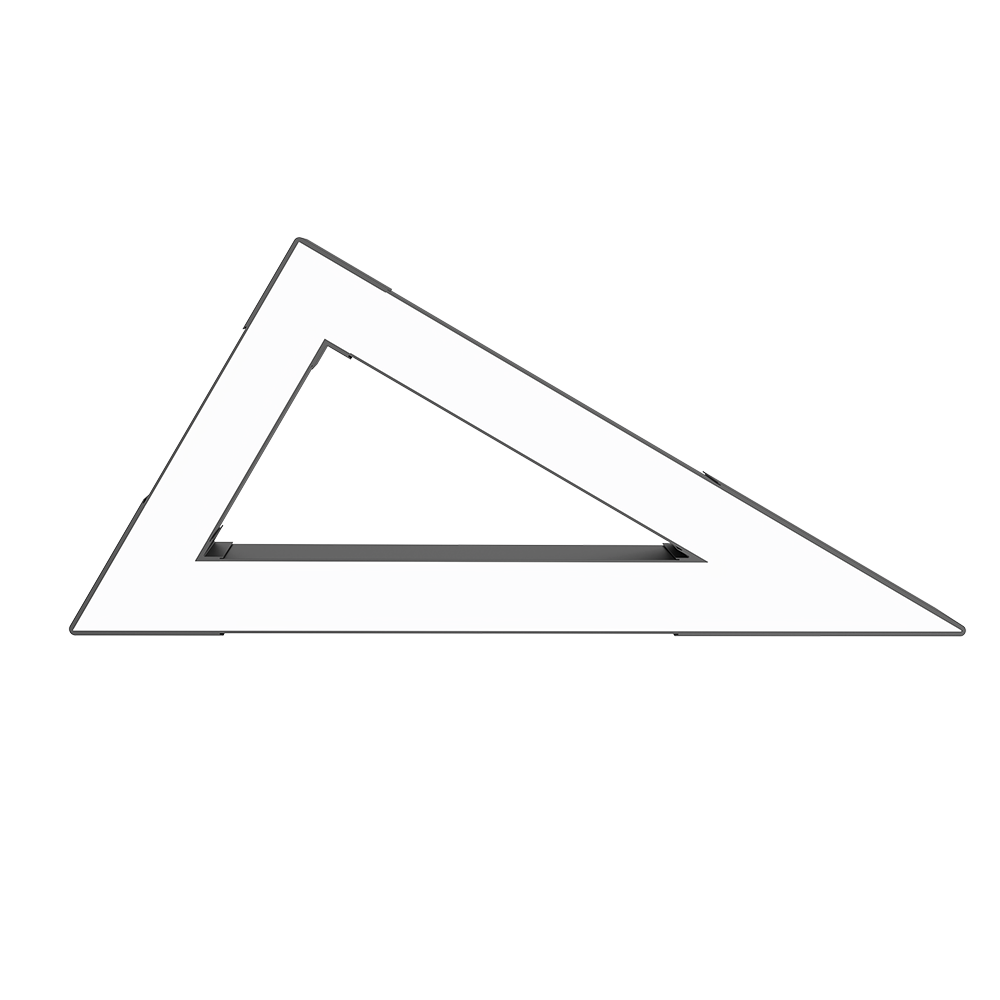

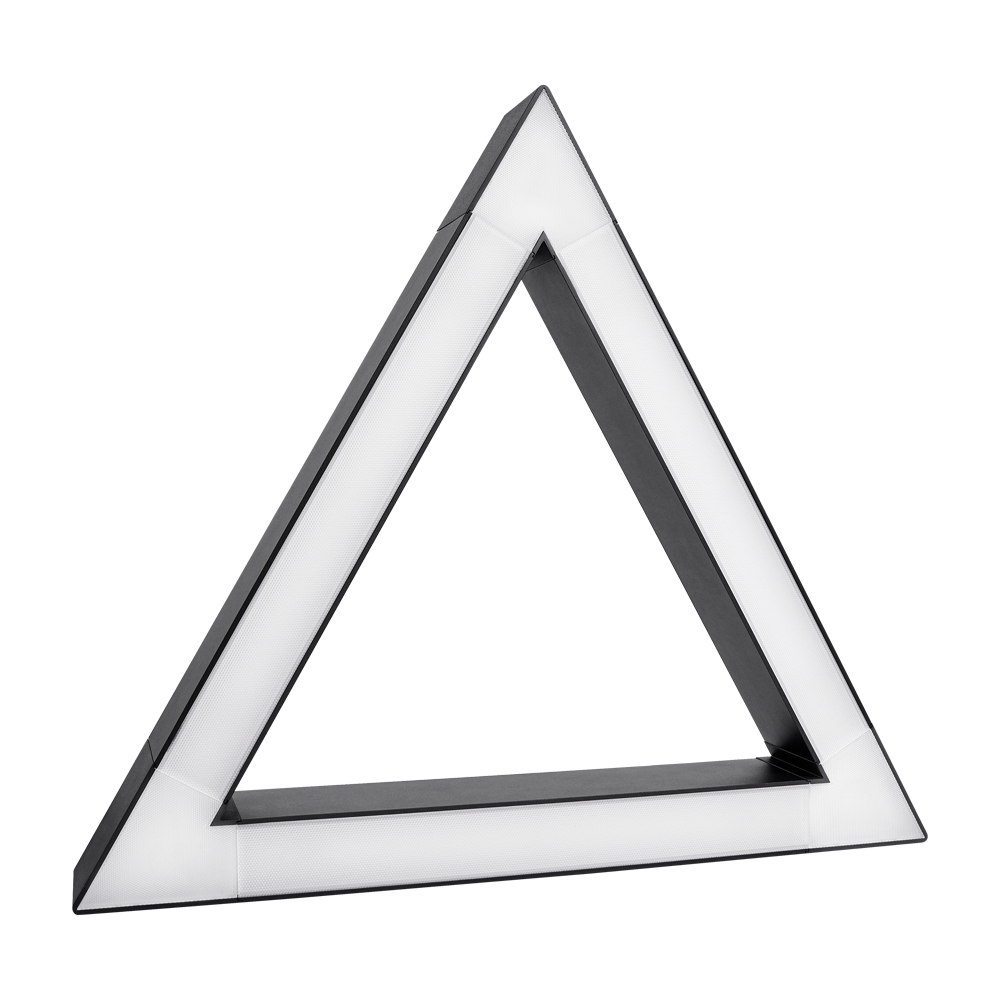

More Designs for Spliceable Linear LED Modules

Our Smart Puzzle Series offers a variety of standard products in triangular, hexagonal, and octagonal shapes, plus assorted smaller modular components. With ample creativity, this modular lighting series lets you easily bring unique lighting designs to life—no complex assembly required, just simple combination of our specialized modules.

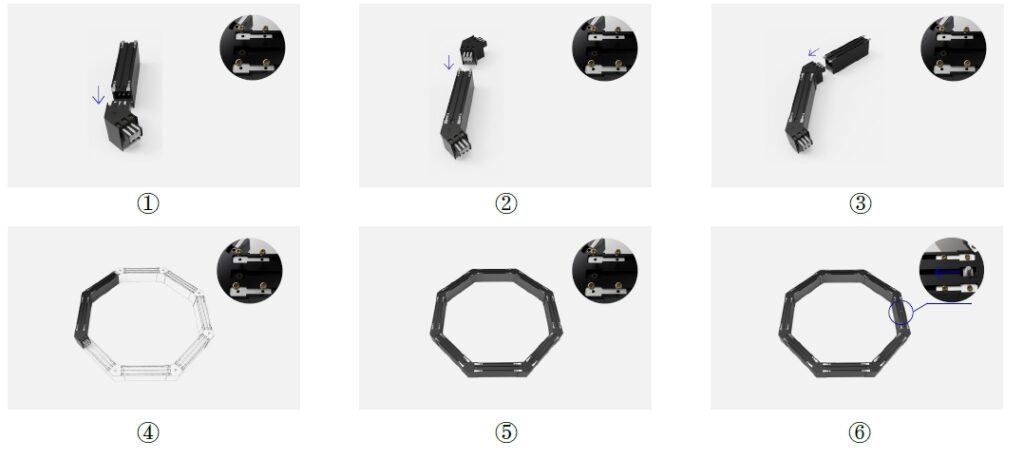

Installation:

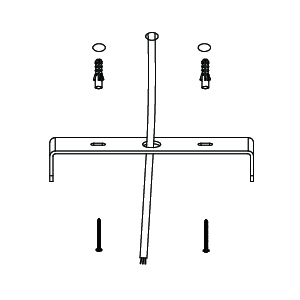

Step 1:Assembly product

Please assemble the modules corresponding to the correct angles.

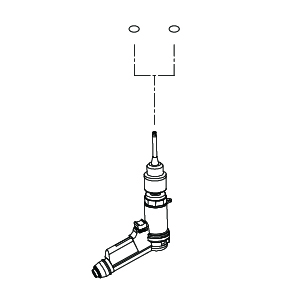

Step 2:Install

Please make sure that the place of installation could stand 10 times the weight of itself before installing in a place where is no vibration,

no swing, and no fire risk.

in the appropriate locations on the

wooden board or cement wall.

hole;Use screws to secure

the bracket to the rubber plugs.

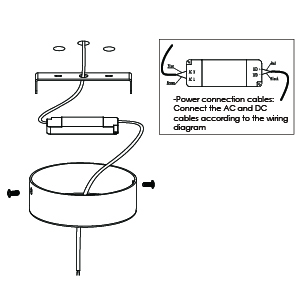

the power directly into the ceiling

plate.Install the ceiling plate lock

on the bracket

the locking device on the ceiling

plate.

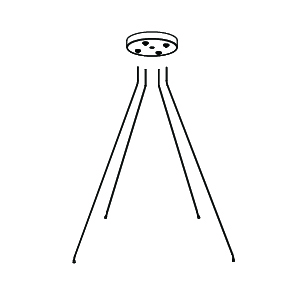

hanging rope, adjust to the desired

height and position, and the installation

is complete.

the AC power line of the light fixture

to the mains power supply.

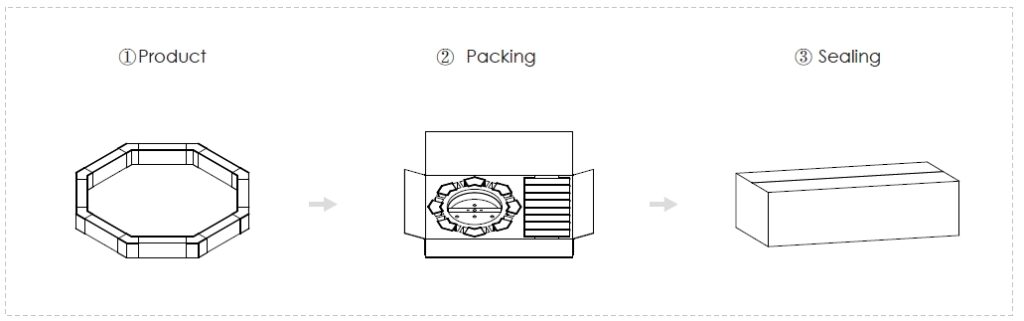

Packing

| Model | HL-PB5075A-E81 | Carton box | 860mm*480mm*440mm |

| Inner box | 840mm*460mm*100mm | QTY/Carton | 4 PCS |

| NW | 7.3kg/PCS | GW | 8.2kg/PCS |

USER INSTRUCTIONS

- The installation of the unit must be done by a qualified electrician.

- The unit must be earthed in case an earth connecting point exists.

- Ensure that the mains is switched off during servicing.

- Do not use bulb(s) bigger than the indicated on units name-plate or packaging.

- Ensure that after the installation,the unit is properiy fixed and the cable clamps (if exist)are well tighened.

- Manufacturer will not accept liability for injury or damage resulting from incorrect use or installation.

Why choose Helian’s LED module lights ?

Shenzhen Helian Electronics (HLLED)—founded 2007, ISO 9001-certified, and a leading modular LED lights maker. Our flagship Smart Puzzle Series has DIY splicing, 30°-120° angle modules, plus low transport and maintenance costs. It’s CE/ROHS/UL-certified; our modular geometric lighting fits commercial and home use. With 18+ years’ expertise, we serve 170+ countries, delivering innovative LED module lights solutions that mix functionality and design.

For this Modular Octagon Lighting product, we offer custom procurement, OEM/ODM services.

Our Smart Puzzle Series modular LED lights support flexible DIY splicing for custom designs.

Features PUSH-IN shrapnel wiring & built-in power for easy install and maintenance.

Ensures even light output, CE/ROHS/UL certification, and durable matte craftsmanship

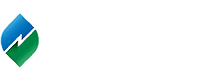

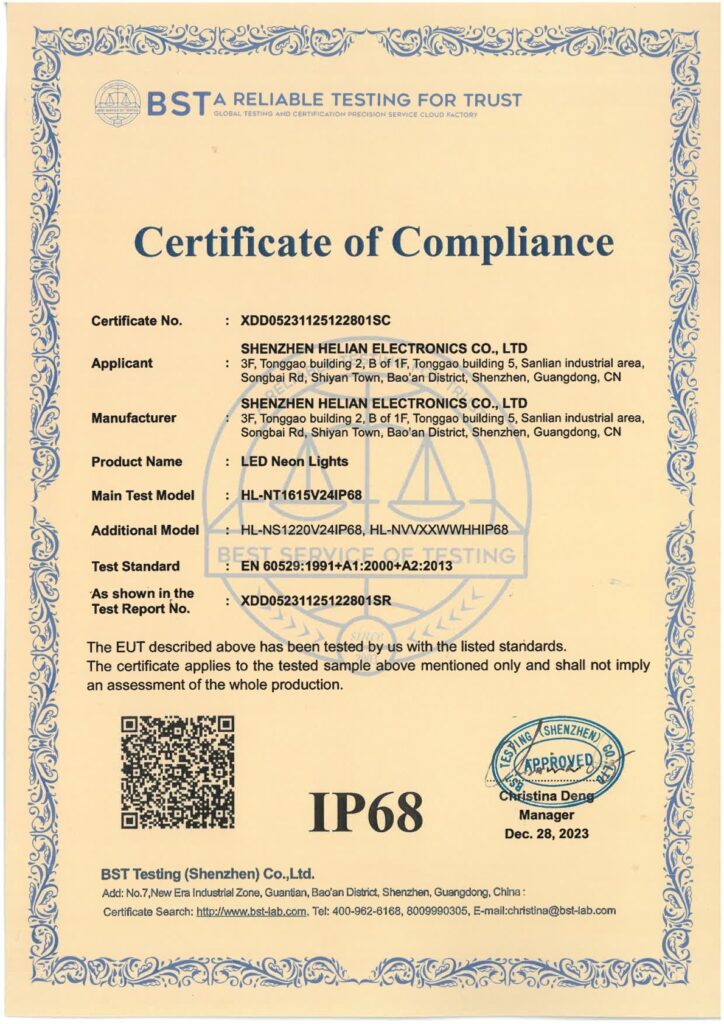

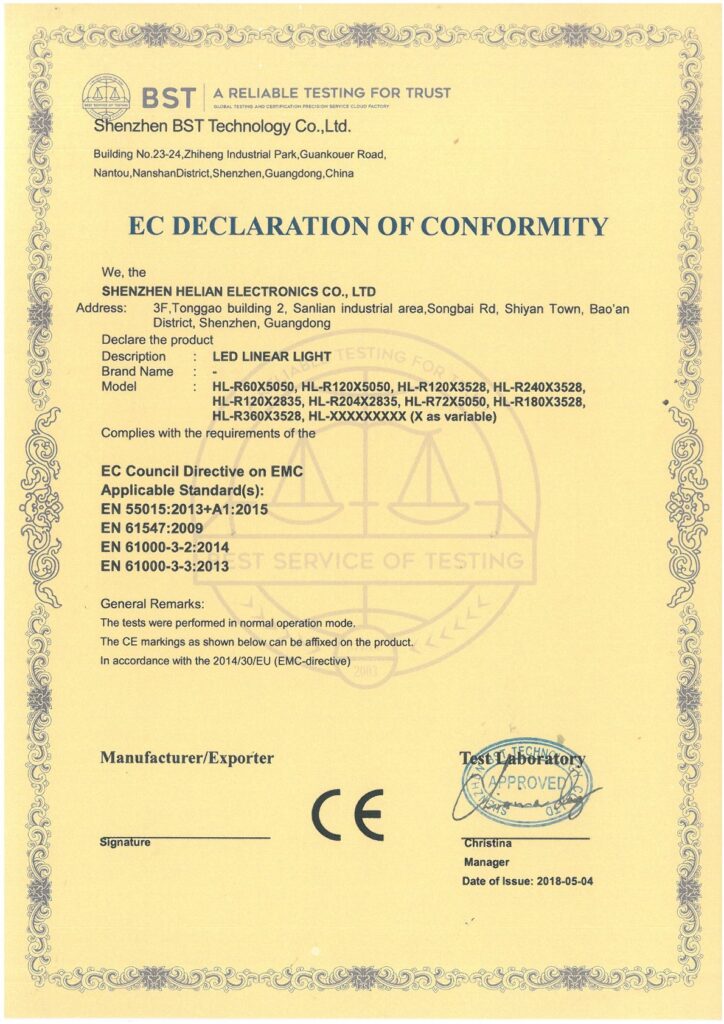

Certificates

Wholesale/purchasing process for Modular Octagon Lighting

Consult customer service

Provide 24-hour online customer service.

Confirm demand

Please sync the model/sku/quantity/customization requirements of the products you need to customer service, we will solve all the problems for you.

Order

After determining your needs, our customer service staff will assist you in placing your order, so there is absolutely nothing to worry about.

Provide delivery

We have the appropriate shipping channels, but of course you can also specify your own shipping service.

Delivery

You will soon receive the products you have purchased.

Checkout

Support T/T, Paypal, Credit Card, Banker’s Acceptance, etc.