What is commercial outdoor lighting?

Commercial outdoor lighting is stable, energy-efficient, and long-lasting. It is designed for outdoor spaces like commercial buildings, landscapes, and sports fields. This lighting provides bright and consistent light for cities and businesses.

the types and benefits of commercial outdoor lighting

Use a clear and attention-grabbing short paragraph to engage your audience and draw them into reading the rest of your content.

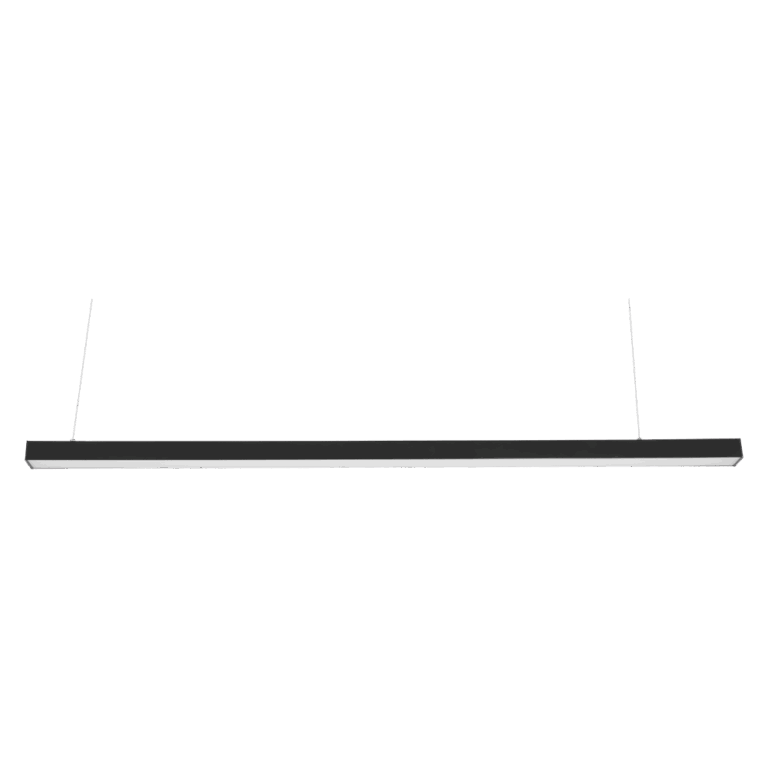

Commercial Exterior Lighting – LED Profile Recommendation

An LED Waterproof Profile is a type of lighting designed for outdoor and wet areas. It protects the lights from water, ensuring they work well in rainy or submerged conditions. These profiles have different waterproof ratings, such as IP65, IP66, IP67, and IP68. A higher number means better waterproof protection.

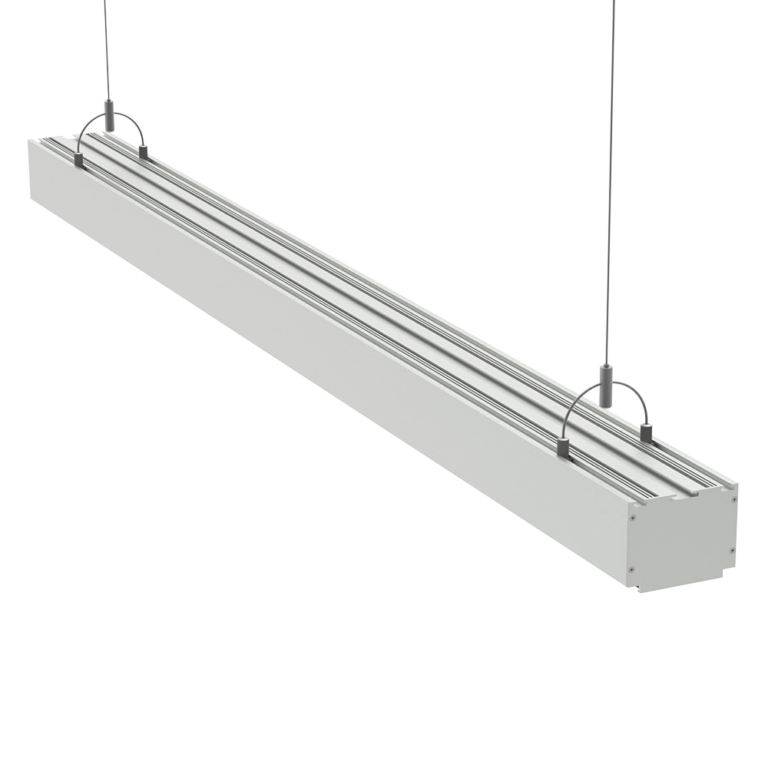

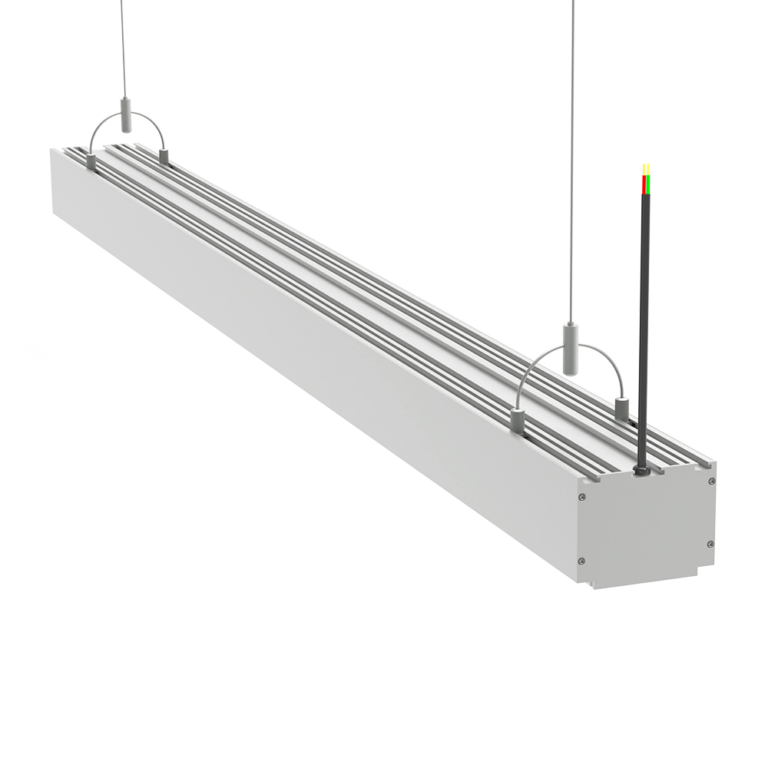

Outdoor LED Light Bar Recommendation

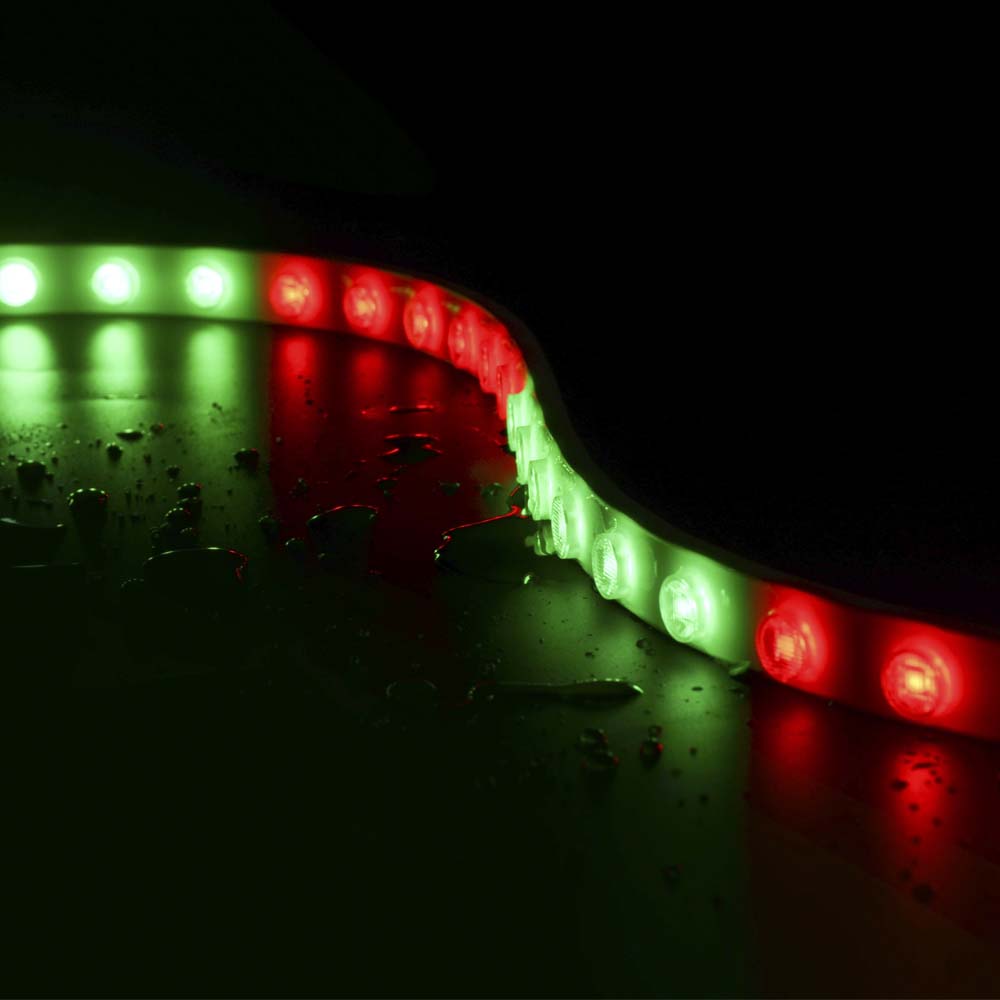

Outdoor LED strips are a smart choice for lighting. They use bright LED chips that give off a lot of light while using little energy. These strips are also waterproof, with protection ratings usually above IP67. Made from eco-friendly flexible silicone, they do not harm the environment. Their flexibility makes them easy to install and cut to the desired length.

Commercial applications of outdoor light strips

Commercial Outdoor Lighting Solutions

Silicone Waterproofing Solutions

Silicone waterproofing is usually achieved through waterproofing processes such as dripping silicone, silicone sleeve, half-sleeve dripping silicone, and silicone pumping. Silicone has excellent elasticity, weather resistance and hydrophobicity, and can effectively prevent water vapor from invading the interior of LED lights.

Advantages of silicone waterproof:

Disadvantages:

PU adhesive (polyurethane adhesive) waterproof

PU adhesive, or polyurethane adhesive, is a popular type of glue used to create a waterproof seal. It’s commonly found in products like flexible LED light strips, helping to protect them from water damage.

Advantages:

Disadvantages:

High quality heat shrinkable tubing for waterproofing

Heat-shrinkable tubing is a particular type of plastic that shrinks when heated. It’s often used to wrap around wires and connections in LED lights. When the tubing is heated, it tightly hugs the cables, creating a waterproof seal to protect them from moisture and damage.

Advantages:

Disadvantages:

Waterproofing with nano waterproof coating

Nano waterproofing involves putting a skinny layer of special coating on the surface of LED lights to make them waterproof. This coating is so fine that it’s hard to see, but it does a great job keeping water out and protecting the lights.

Advantages:

Disadvantages:

The integrated extrusion waterproofing process

Machine one-piece extrusion waterproofing is a specialized method to make LED lights resistant to water. In this process, special machines take waterproof materials, like silicone or PU adhesive, and apply them directly to essential parts of the LED light. This creates a smooth, continuous layer that helps keep water out, ensuring the lights work well even in wet conditions.

Advantages:

Disadvantages:

FAQs

You may want to know more about outdoor commercial lighting!