Note: To ensure and accuracy, this article follows the content creation and review process of the Helian Expert Team.

Introduction

In outdoor LED installation, getting the right aluminum profile thickness and waterproofing tech is key to long – term stable operation. This guide analyzes data from over 200 real – world outdoor projects. It aims to give practical advice to pros and project decision – makers. The well – set target keywords help it be found easily online, providing the most useful info to those who need it.

Industry Misconception:

90% of users only focus on thickness numbers and ignore structure design. In many outdoor LED projects, most users wrongly think the thicker the aluminum profile, the better its performance. But structure design is also super important for system stability and durability. A good structure design can spread external pressure well, greatly strengthening wind resistance. Even with a relatively thin profile, smart structure design can ensure it works well in tough outdoor conditions. (Data source: In – depth research on 200+ outdoor projects)

Thickness and Wind Pressure Resistance Formula:

P=(2×t×σ)/D (t = thickness, σ = material strength). This formula simply shows the link between profile thickness, material strength, and wind pressure resistance. When preparing for a project, use this formula with local wind pressure requirements to accurately calculate the right profile thickness. It provides a solid basis for project safety and stability. (Reference: “Building Structure Load Code”)

Importance of Aluminum Profiles in LED Installations

Aluminum profiles protect LED strips from dust, moisture, and physical impact. They enhance the aesthetics of lighting setups and are crucial for LED heat dissipation, which is vital for LED performance and lifespan.

Why Thickness Matters in Outdoor Applications

Outdoors, thicker profiles offer more structural strength against harsh weather. They also dissipate heat better, preventing LEDs from overheating, which can cause brightness loss, color shift, and premature failure.

Key Factors Affecting Thickness Selection

When choosing the right thickness, consider structural strength, heat dissipation, weather resistance, aesthetics, weight – performance balance, and cost.

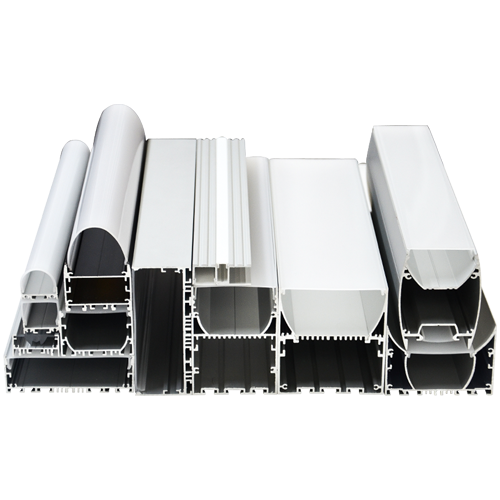

Understanding Aluminum Profiles for LED Installations

What Are Aluminum LED Profiles?

Aluminum LED profiles, or LED channels/extrusions, are high – quality aluminum housings for LED strips. They come in various shapes, sizes, and finishes for versatile installations.

Role of Aluminum in LED Housing and Heat Dissipation

Aluminum’s high thermal conductivity makes it an ideal heat sink. It draws heat away from LEDs, keeping them cool for better performance, longer lifespan, and less color degradation.

Types of Aluminum Profiles Used in Outdoor LED Installations

Common types include linear profiles for continuous light along paths, recessed profiles for a sleek look (e.g., decks, steps), surface – mounted profiles for general illumination, and spot profiles for directed light.

Key Factors Affecting Aluminum Profile Thickness Selection

- Structural Strength and Durability

Thicker profiles offer more structural strength. In areas with high wind or physical stress, like coastal regions, they prevent bending and breakage. - Heat Dissipation and Thermal Management

Heat dissipation is crucial for LED performance. Thicker profiles have more surface area and mass to absorb and dissipate heat, especially in high – power or hot – climate applications. - Weather Resistance and Corrosion Protection

Outdoor profiles face moisture, rain, humidity, and UV rays. Thicker profiles resist these better, and coatings like anodizing or powder – coating enhance corrosion protection. - Aesthetic and Design Considerations

Thicker profiles suit bold industrial designs; thinner ones are more modern. Choose thickness to match the outdoor space’s design concept. - Weight vs. Performance Trade – offs

Thicker profiles are heavier. When installing on lightweight structures or prioritizing ease of installation, balance performance and weight. - Cost Considerations and Budget Constraints

Thicker profiles cost more. Find a cost – effective option that meets project requirements within your budget.

Outdoor LED Aluminum Profile Thickness Decision Table

Because coastal areas are very different from inland areas, especially with their high salt levels, LED aluminum profiles used for outdoor lights are more likely to get corroded. To find the right thickness for metal profiles, we did many tests, including a salt spray test. Here are our suggestions:

| Environment Conditions | Recommended Thickness | Test Standard |

| Coastal High – Salt Spray | 2.5 – 3.0mm | ASTM B117 1000hrs. This standard tests aluminum profiles in a simulated high – salt spray environment for 1000 hours. After such a tough test, 2.5 – 3.0mm thick profiles can keep good physical properties and corrosion resistance in harsh coastal high – salt spray conditions, ensuring outdoor LED system operation. |

| Inland Normal Climate | 1.8 – 2.2mm | ISO 9227. This standard assesses material corrosion resistance in normal atmospheric conditions. 1.8 – 2.2mm thick profiles passing this test can meet long – term operation needs of outdoor LED projects in inland normal climate. |

Recommended Thicknesses for Different Outdoor LED Applications

Residential Outdoor LED Lighting (Patios, Gardens, Pathways)

1.5 – 2.0 mm thickness usually suffices. These areas focus on creating a pleasant atmosphere and have lower structural and heat – dissipation needs.

Commercial Outdoor LED Installations (Parking Lots, Storefronts)

2.0 – 3.0 mm is recommended. These areas need more durability and better heat dissipation due to harsher conditions.

Industrial and Heavy – Duty Outdoor LED Installations

3.0 mm or thicker is advisable to withstand rough handling, vibrations, and extreme conditions.

Architectural and Decorative Outdoor LED Applications

1.5 – 2.5 mm range is common, balancing aesthetics and functionality.

Common Aluminum Thickness Standards and Measurements

Gauge vs. Millimeter Measurements

Aluminum thickness can be measured in gauges (non – metric, lower number means thicker) or millimeters. Millimeters are more common in the metric system. For example, 16 – gauge is about 1.524 mm, and 20 – gauge is about 0.813 mm.

Standard Thickness Options Available in the Market

Market options range from 1.0 mm to 5.0 mm or more. The 1.5 – 3.0 mm range is most common for various outdoor LED needs.

How to Choose the Right Standard for Your Project

Consider structural, heat – dissipation, and cost needs. Millimeters are more convenient in metric countries. Ensure compatibility if using imported materials or specific industry standards.

Corrosion Resistance and Outdoor Longevity

Effects of Moisture, Rain, and Humidity on Aluminum Profiles

These elements can cause corrosion, weakening the profile, affecting appearance, and reducing LED protection. Water ingress can also cause electrical issues.

Anodized vs. Powder – Coated Aluminum for Outdoor Durability

Anodized aluminum has a protective oxide layer from an electrochemical process, offering good corrosion resistance. Powder – coated aluminum has a baked – on powder paint, providing more color options, better scratch resistance, and a more uniform finish. Both are suitable for outdoors.

Best Coating and Finishing Options to Prevent Corrosion

Besides anodizing and powder – coating, galvanizing (applying zinc) adds protection, especially in corrosive environments. A primer – top – coat combination can also enhance corrosion resistance.

How to choose the waterproof process for LED profiles?

The waterproof process of LED light profiles is extremely significant. The following comparison chart of the most prevalent waterproof processes may help you choose outdoor LED profiles.

| Waterproofing Process | Applicable Thickness Range of LED Profiles (mm) | Lifespan Range (Years) | Application Scenarios |

| Epoxy Dripping Waterproofing | Generally thin, specifically determined by design | 2-5 | Urban contour lighting (e.g., buildings, advertising walls), indoor decorative lighting |

| Hollow Full Sleeve Waterproofing | Moderate, specifically determined by sleeve size | 3-8 | Outdoor billboards, street lighting (non-extreme weather areas) |

| Half Sleeve Epoxy Dripping/Potting Waterproofing | Moderate to thick, specifically determined by design | 3-10 | Decorative applications with irregular designs (e.g., hotels, nightclubs), outdoor landscape lighting |

| Full Sleeve Potting/Vacuum Potting Waterproofing | Thicker, providing higher waterproof rating | 5-15 | LED pool lights, underwater lighting, outdoor lighting in extreme weather areas |

| PECVD Nano-Coating Waterproofing Technology | Widely applicable, extremely thin coating (nano-scale) | 5-15+ (depending on other factors such as LED quality and power supply) | Urban street lighting, shopping mall exterior LED displays, outdoor LED strips |

| Parylene Nano Waterproofing | Widely applicable, extremely thin coating (micron-scale) | 5-15+ | High-demand waterproof environments, such as offshore platforms, industrial equipment interior lighting, salt spray and voltage resistance applications |

- Applicable Thickness Range of LED Profiles:

Since the thickness of LED profiles can vary based on specific designs and application requirements, the thickness ranges provided in the table are general descriptions. In practical use, selections should be made based on specific designs and product specifications. - Lifespan Range:

Lifespan is influenced by multiple factors, including LED quality, power supply stability, environmental conditions (e.g., temperature, humidity, UV exposure), and the quality of the waterproofing process. Therefore, the lifespan ranges provided in the table are estimated values, and actual lifespans may vary based on specific circumstances. - Application Scenarios:

The application scenarios listed in the table are general descriptions. In practical use, they may vary based on specific needs and conditions. When selecting a waterproofing process, it is important to fully consider the application environment, cost budget, and performance requirements.

Heat Dissipation: How Thickness Impacts LED Performance

- The Science Behind Heat Dissipation in LED Fixtures

LEDs generate heat during operation. Heat dissipation occurs through conduction, convection, and radiation. Aluminum profiles act as heat sinks, conducting heat away from LEDs. - How Thickness Affects Thermal Conductivity

Thicker profiles have higher thermal mass and larger cross – sectional areas for heat transfer. They conduct heat more effectively and have more surface area for dissipation, improving LED thermal management. - Best Practices for Optimizing Heat Management

Ensure proper ventilation around the profile. Avoid overcrowding LEDs. Choose a suitable surface finish (rough or textured for more surface area). Clean the profile regularly to remove dust and debris.

Installation Considerations Based on Profile Thickness

Compatibility with LED Strips and Accessories

Profile thickness should match LED strips and accessories. Thicker profiles may need larger strips or different brackets. Ensure a snug fit for good heat transfer and secure installation.

Handling and Mounting Best Practices

Handle thick profiles carefully, using proper equipment. Align mounting holes and tighten fasteners securely. For thin profiles, avoid over – tightening.

Ensuring Secure and Long – Lasting Installations

Use high – quality hardware, choosing corrosion – resistant options in coastal areas. Seal gaps to prevent water ingress and inspect installations regularly.

Compliance and Industry Standards

UL and CE Certification for Outdoor LED Installations

UL certification ensures US safety and performance standards compliance. CE marking shows EU health, safety, and environmental protection regulations compliance. Certified products are more reliable.

Building Codes and Safety Regulations

Building codes vary but generally cover electrical safety, structural integrity, and fire resistance. Outdoor LED installations must comply.

Environmental Considerations and Sustainability

Aluminum is recyclable. Choosing recycled profiles promotes sustainability. Also, consider LED system energy efficiency to reduce environmental impact.

Hot Products

If you’re looking for LED profiles for outdoor lighting, don’t be afraid to take a look at these products:

Summary: Choosing the Best Aluminum Profile Thickness

Consider structural strength, heat dissipation, weather resistance, aesthetics, weight, cost, and industry standards when choosing thickness.

Residential: 1.5 – 2.0 mm; Commercial: 2.0 – 3.0 mm; Industrial/Heavy – Duty: 3.0 mm or more; Architectural/Decorative: 1.5 – 2.5 mm.

Consult manufacturers or lighting experts. Consider project details like location, LED type, and budget. Don’t compromise on quality.